Wholesale Syringe Manufacturing Business - Virus Sampling Tube Assembling Line – IVEN

Wholesale Syringe Manufacturing Business - Virus Sampling Tube Assembling Line – IVEN Detail:

Brief Introduction:

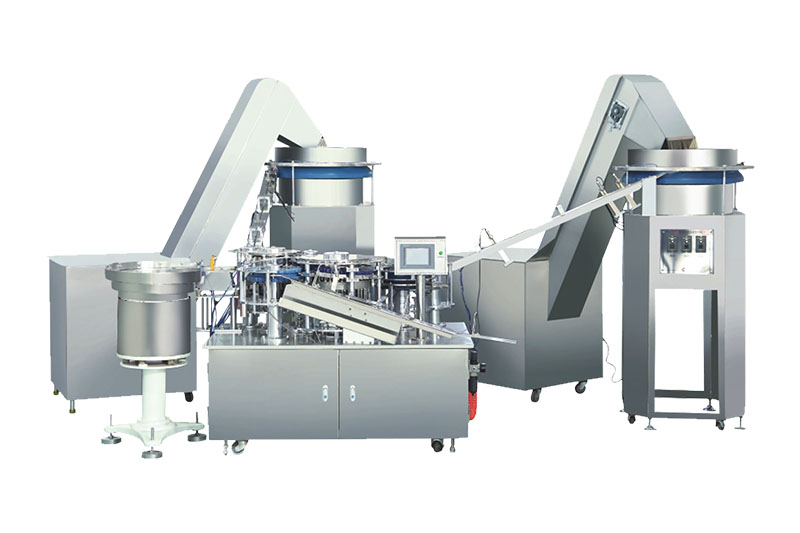

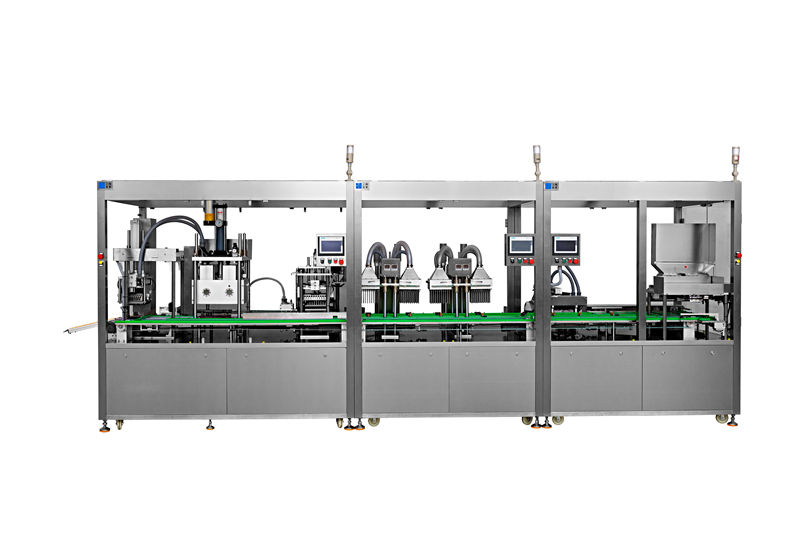

Our Virus Sampling Tube Assembling Line is mainly used for filling transport medium into virus sampling tubes. It with high degree of automation, high production efficiency, and have a good process control and quality control.

Product Video

Production Process:

Manually loading the test tube and cap into the hopper, and put additive into the reagent bottle→automatic tube loading → Tube missing detection → Dosing(two group of dosing systems, each group has 5 nozzles) → Cap feeding → crew capping → Detection of screw capping in place → Dosing volume detection → Automatic rejection (optional) → Automatic tube out feeding

Technical Parameters

|

Virus Sampling Tube Production Line |

|

| Capacity | ≥5000-6000 tubes/hour |

| Applicable tube type | According to customer provided samples. |

| Overall dimension | 2000*1800*1500mm |

| Power supply | three phase, 380V, 50Hz |

| Electric power | 2.5Kw |

| Air supply | 0.6-0.8Mpa, <100L/min |

| Weight | 900KG |

| Dosing station | 2 groups, with 5 dosing heads, precision ceramic injection pump |

| Filling accuracy | ≥±97% (base on 3ml) |

| Capping station | 5 heads |

Main Configuration Table

|

No. |

Main Parts |

Main Brands |

|

1 |

Pneumatic Components | Cylinder and Electromagnetic valve from AIRTAC, and Electric cylinder from AIM, which ensure the stability and long-term running. |

|

2 |

Electrical Appliance |

Electrical components from Schneider (France), Detecting element from Omron (Japan), PLC from Mitsubishi (Japan), HMI from Siemens (Germany), Servo Motor from Panasonic (Japan). |

|

3 |

Dosing Devices |

FMI ceramic metering pump. Chinese precision ceramic injection pump. Japanese solenoid valves |

|

4 |

Main Structure |

Stainless steel sheet with nano-treatment, steel structure frame, high-quality aluminum alloy, stable and reliable, easy to clean. Meet GMP standard. |

Product detail pictures:

Related Product Guide:

Our primary objective is always to offer our clients a serious and responsible small business relationship, offering personalized attention to all of them for Wholesale Syringe Manufacturing Business - Virus Sampling Tube Assembling Line – IVEN , The product will supply to all over the world, such as: Sweden, Islamabad, Southampton, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.

Send your message to us:

Write your message here and send it to us