Wholesale Syringe Manufacturing Business - Virus Sampling Tube Assembling Line – IVEN

Wholesale Syringe Manufacturing Business - Virus Sampling Tube Assembling Line – IVEN Detail:

Brief Introduction:

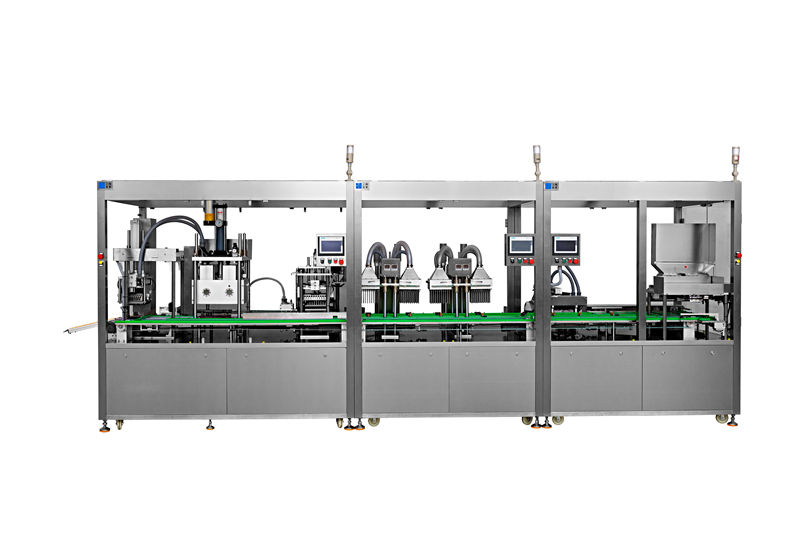

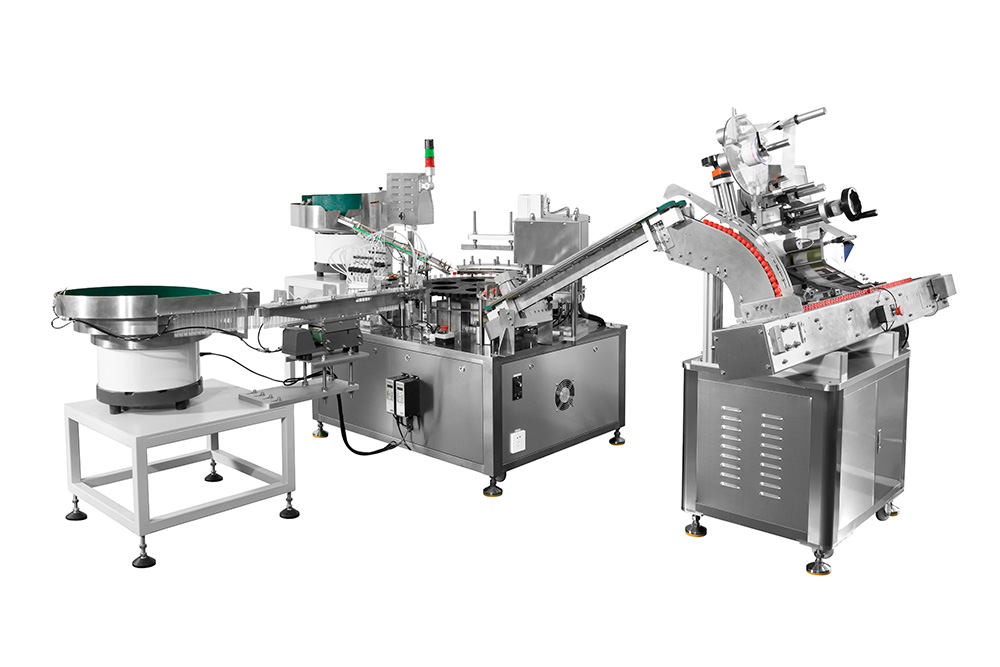

Our Virus Sampling Tube Assembling Line is mainly used for filling transport medium into virus sampling tubes. It with high degree of automation, high production efficiency, and have a good process control and quality control.

Product Video

Production Process:

Manually loading the test tube and cap into the hopper, and put additive into the reagent bottle→automatic tube loading → Tube missing detection → Dosing(two group of dosing systems, each group has 5 nozzles) → Cap feeding → crew capping → Detection of screw capping in place → Dosing volume detection → Automatic rejection (optional) → Automatic tube out feeding

Technical Parameters

|

Virus Sampling Tube Production Line |

|

| Capacity | ≥5000-6000 tubes/hour |

| Applicable tube type | According to customer provided samples. |

| Overall dimension | 2000*1800*1500mm |

| Power supply | three phase, 380V, 50Hz |

| Electric power | 2.5Kw |

| Air supply | 0.6-0.8Mpa, <100L/min |

| Weight | 900KG |

| Dosing station | 2 groups, with 5 dosing heads, precision ceramic injection pump |

| Filling accuracy | ≥±97% (base on 3ml) |

| Capping station | 5 heads |

Main Configuration Table

|

No. |

Main Parts |

Main Brands |

|

1 |

Pneumatic Components | Cylinder and Electromagnetic valve from AIRTAC, and Electric cylinder from AIM, which ensure the stability and long-term running. |

|

2 |

Electrical Appliance |

Electrical components from Schneider (France), Detecting element from Omron (Japan), PLC from Mitsubishi (Japan), HMI from Siemens (Germany), Servo Motor from Panasonic (Japan). |

|

3 |

Dosing Devices |

FMI ceramic metering pump. Chinese precision ceramic injection pump. Japanese solenoid valves |

|

4 |

Main Structure |

Stainless steel sheet with nano-treatment, steel structure frame, high-quality aluminum alloy, stable and reliable, easy to clean. Meet GMP standard. |

Product detail pictures:

Related Product Guide:

We have quite a few great team customers very good at internet marketing, QC, and dealing with kinds of troublesome trouble while in the output approach for Wholesale Syringe Manufacturing Business - Virus Sampling Tube Assembling Line – IVEN , The product will supply to all over the world, such as: Ukraine, Swedish, Marseille, We provide good quality but unbeatable low price and the best service. Welcome to post your samples and color ring to us .We will produce the goods according to your request. If you are interested in any products we offer, please feel free to contact us directly by mail, fax, telephone or internet. We are here to answer your questions from Monday to Saturday and looking forward to cooperating with you.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

Send your message to us:

Write your message here and send it to us