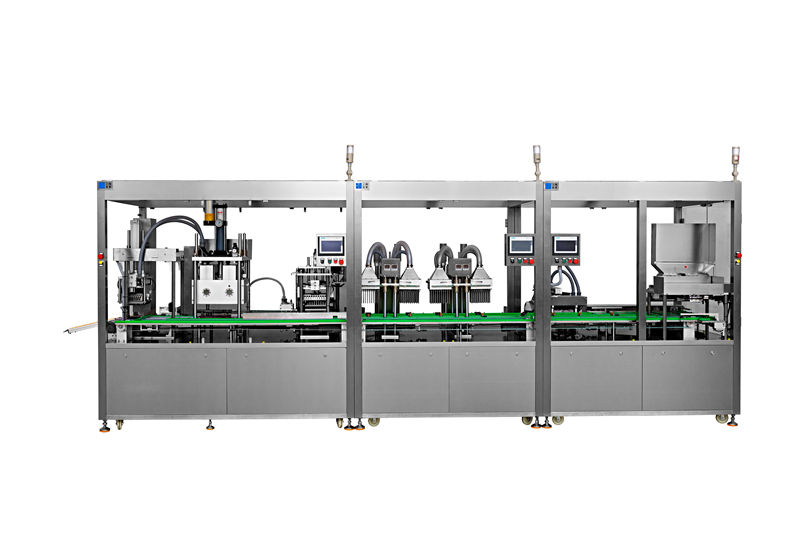

Wholesale Price Vial Filling Turnkey Plant - Pharmaceutical RO Water Treatment system – IVEN

Wholesale Price Vial Filling Turnkey Plant - Pharmaceutical RO Water Treatment system – IVEN Detail:

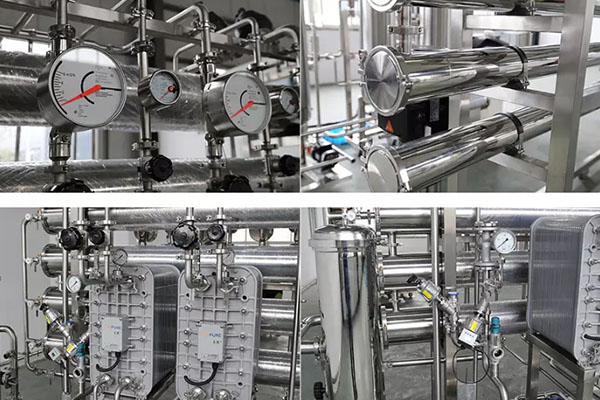

Pharmaceutical RO Water Treatment system

Introduction:

Reverse osmosis is the eighties developed a membrane separation technology, which mainly use the semipermeable membrane permeation principle, to give it a certain way by applying a pressure on the natural infiltration direction against the force of the water in the concentrated solution dilute the solution to penetrate this way is called reverse osmosis. By the components of the device is reverse osmosis reverse osmosis unit.

One, two reverse osmosis + EDI preparation (purified water process characteristics)

1 Suitable for raw water salinity compared Height regions;

2 product water conductivity is better;

3 one-time investment of less;

4 lower operating costs;

5.Stability.

Product Video

Parameters:

|

Model |

Water yield (m³/h) |

Minimum water(m³/h) |

Desalinated water(%) |

Working temperature(℃) |

|

FST0.5-A |

0.5 |

1.0 |

98 |

5-35 |

|

FST1-A |

1.0 |

1.5 |

98 |

5-35 |

|

FST2-A |

2.0 |

3.0 |

98 |

5-35 |

|

FST3-A |

3.0 |

4.5 |

98 |

5-35 |

|

FST4-A |

4.0 |

6.0 |

98 |

5-35 |

|

FST6-A |

6 |

8.5 |

98 |

5-35 |

|

FST8-A |

8 |

11.5 |

98 |

5-35 |

|

FST10-A |

10 |

14 |

98 |

5-35 |

|

FST15-A |

15 |

21 |

98 |

5-35 |

|

FST20-A |

20 |

28 |

98 |

5-35 |

|

FST25-A |

25 |

35 |

98 |

5-35 |

|

FST30-A |

30 |

42 |

98 |

5-35 |

Pure steam generator

Introduction

1.Manufactured according to the criteria of JB20031-2004 Pure Steam Generator, our LCZ pure steam generator uses steam heating to produce high-purity steam without heat source. The generator is applicable to sterilization and can effectively prevent secondary pollution resulting from heavy metal, heat source and other impurity heaps. The equipment is characterized by advanced technology, unique design, compact structure, rational configuration and good heat preservation to the shell, which brings about lower heat loss, higher heat efficiency, smaller floor space coverage, easy operation and installation and good adjustability. Our generator complies with the GMP criteria of the State and has been widely applied to the sterilization in health care, pharmaceuticals and food industry.

2. Component part: water source and level purifying water tank

The tank heats the deionized water by steam from the boiler so as to generate high-purity steam. Preheater and evaporator of the tank adopt the intensive seamless stainless steel tube and with good heat transfer. The tank can automatically adjust water inflow according to the steam temperature in the boiler so as to increase the pure steam output. In addition, high-purity steam with different backpressures and flow rates can be obtained by adjusting the outlet valve.

3. This equipment is available in three types, i.e. full-automation, semi-automation and manual operation to meet the requirements of different users.

Main technical parameters

|

Model |

Total Power(KW) |

Pure steam production(L/h) |

Heating steam consumption(kg/h) |

Purified water consumption(kg/h) |

Dimensions(mm) |

|

LCZ-100 |

0.75 |

≥100 |

125 |

120 |

1150×550×2600 |

|

LCZ-200 |

0.75 |

≥200 |

250 |

240 |

1150×900×2700 |

|

LCZ-300 |

0.75 |

≥300 |

375 |

360 |

1400×900×2700 |

|

LCZ-400 |

0.75 |

≥400 |

500 |

480 |

1400×950×2700 |

|

LCZ-500 |

0.75 |

≥500 |

630 |

600 |

1500×1050×2900 |

|

LCZ-600 |

0.75 |

≥600 |

755 |

720 |

1600×1100×2900 |

|

LCZ-700 |

0.75 |

≥700 |

875 |

840 |

1700×1100×2900 |

|

LCZ-800 |

0.75 |

≥800 |

1005 |

960 |

1750×1100×3000 |

|

LCZ-1000 |

1.1 |

≥1000 |

1260 |

1200 |

1750×1100×3000 |

|

LCZ-1500 |

1.1 |

≥1500 |

1890 |

1800 |

1850×1200×3200 |

|

LCZ-2000 |

1.1 |

≥2000 |

2500 |

2400 |

2350×1250×3300 |

WFI Distiller

Brief Introduction

Our LD multi-effect water distillator is designed and manufactured according to the criteria of GB150-1998 Steel Pressure Vessel and JB20030-2004 Multi-effect Water Distillator. All the components and parts of the equipment are made of the 304 or 316L stainless steel. The distilled water generated from the water distillator is of high purity and without heat source, which is in full compliance with all the quality indicators of water for injection stipulated in the Chinese Pharmacopoeia (2010 edition). This equipment proves to be an ideal choice for manufacturers of such pharmaceuticals as various blood products, injections, and infusion solutions, biological antimicrobial agents as well as drinking distilled water.

Main Features

1. This equipment is available in three types, i.e. full-automation, semi-automation and manual operation to meet the requirements of different users.

2. Water distillator with more than six effects needs not to add cooling water.

Main Parameters

|

Model |

Motor power (kw) |

Water yield (L/h) |

steam consumption (kg/h) |

raw water consumption (kg/h) |

outline dimension (mm) |

|

LD500-6 |

0.75 |

≥500 |

≤120 |

550 |

2190×1150×3000 |

|

LD750-6 |

0.75 |

≥750 |

≤180 |

825 |

2580×1240×3400 |

|

LD1000-6 |

1.1 |

≥1000 |

≤240 |

1100 |

2580×1240×3500 |

|

LD1500-6 |

1.1 |

≥1500 |

≤360 |

1650 |

3240×1300×4000 |

|

LD2000-6 |

2.2 |

≥2000 |

≤480 |

2200 |

3240×1300×4100 |

|

LD3000-6 |

2.2 |

≥3000 |

≤720 |

3300 |

3680×1500×4200 |

|

LD4000-6 |

2.2 |

≥4000 |

≤960 |

4400 |

4300×1700×4600 |

|

LD5000-6 |

4.0 |

≥5000 |

≤1200 |

5500 |

4400×1700×4600 |

|

LD6000-6 |

4.0 |

≥6000 |

≤1400 |

6600 |

4600×1750×4800 |

|

LD7000-6 |

4.0 |

≥8000 |

≤1920 |

8800 |

5000×1850×4900 |

|

LD10000-6 |

4.0 |

≥10000 |

≤2400 |

11000 |

5600×2050×5200 |

Purified Water EDI Treatment System

Introduction:

1.Reverse osmosis is a kind of membrane separation technology developed since the 1980s.

2.It mainly uses the osmosis principle if semi-transparent membrane. A pressure that is called reverse osmosis.

3.The device that is composed of reverse osmosis components is called reverse osmosis device.

Primary and secondary reverse osmosis+EDI

1.Applied in areas where the salinity of raw water is high;

2.Good electric conductivity of water produced;

3.Low investment;

4.Low operating cose;

5.Good stability.

Technical characteristics

1. Modularity design, compact structure.

2. System can choose thermal disinfection RO membrane and thermal disinfection EDI; the whole system can realize on-line hot water disinfection.

3. Double softener can achieve series connections by using the valve group and generation alternatively.

4. Feed water pump.1st stage high pressure pump and 2nd stage high pressure pump are all controlled by frequency.

5. System terminal water production uses a dual supply mode

6. Using the middle water storage tank as the buffer tank to realize cleaning on-line, dispensing with separate cleaning system.

7. Making stainless steel tube directly tensile bending in the pipeline as far as possible, avoid welding.

8. For the connection of the pipeline and the spare parts, it adopts the arc to protect the automatic welding track, and to ensure the welding quality

9. Control system: PLC automatic control technology

10. Recording mode: You can choose the paperless recorder for paperless records and also the paper record the key parameters in real time.

| Item |

Water Yield (m3 /h ) |

Minimum Water Inflow (m3 /h ) |

Desalted Water (%) |

Working Water Tempterature (°C) |

|

FST0.5-A |

0.5 |

2.0 |

98 |

5-35 |

|

FST1-A |

1.0 |

2.5 |

98 |

5-35 |

|

FST2-A |

2.0 |

3.6 |

98 |

5-35 |

|

FST3-A |

3.0 |

5.0 |

98 |

5-35 |

|

FST4-A |

4.0 |

6.5 |

98 |

5-35 |

|

FST6-A |

6.0 |

8.5 |

98 |

5-35 |

|

FST8-A |

8.0 |

11.0 |

98 |

5-35 |

|

FST10-A |

10.0 |

13.5 |

98 |

5-35 |

|

FST15-A |

15.0 |

20.0 |

98 |

5-35 |

|

FST20-A |

20.0 |

26.0 |

98 |

5-35 |

|

FST25-A |

25.0 |

35.0 |

98 |

5-35 |

|

FST30-A |

30.0 |

40 |

98 |

5-35 |

Product detail pictures:

Related Product Guide:

Good quality comes 1st; assistance is foremost; business enterprise is cooperation is our business enterprise philosophy which is regularly observed and pursued by our company for Wholesale Price Vial Filling Turnkey Plant - Pharmaceutical RO Water Treatment system – IVEN , The product will supply to all over the world, such as: Marseille, Tanzania, Los Angeles, We adhere to client 1st, top quality 1st, continuous improvement, mutual advantage and win-win principles. When cooperation together with the customer, we provide shoppers with the highest high-quality of service. Established good business relations using the Zimbabwe buyer inside the business, we've got established own brand and reputation. At the identical time, wholeheartedly welcome new and old prospects to our company to go to and negotiate small business.

With a positive attitude of regard the market, regard the custom, regard the science, the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.