Vacuum blood collection tube turnkey plant

IVEN’s integrated engineering solutions for pharmaceutical and medical factory include the clean room, auto-control and monitoring system, pharmaceutical water treatment system, solution preparing and conveying system, filling and packing system, automatic logistics system, quality control system, central laboratory and etc. Focused on customers’ individual requirements, IVEN customizes engineering solutions meticulously for users on:

IVEN Pharmatech is the pioneer supplier of turnkey plants that provides integrated engineering solution for worldwide pharmaceutical factory such as IV solution, vaccine, oncology etc., in compliance with EU GMP, US FDA cGMP, PICS, and WHO GMP.

We provide the most reasonable project design, the high quality equipment and the customized service to different pharmaceutical and medical factories from A to Z for Non-PVC soft bag IV solution, PP bottle IV solution, Glass vial IV solution, Injectable Vial & Ampoule, Syrup, Tablets & Capsules, Vacuum blood collection tube etc.

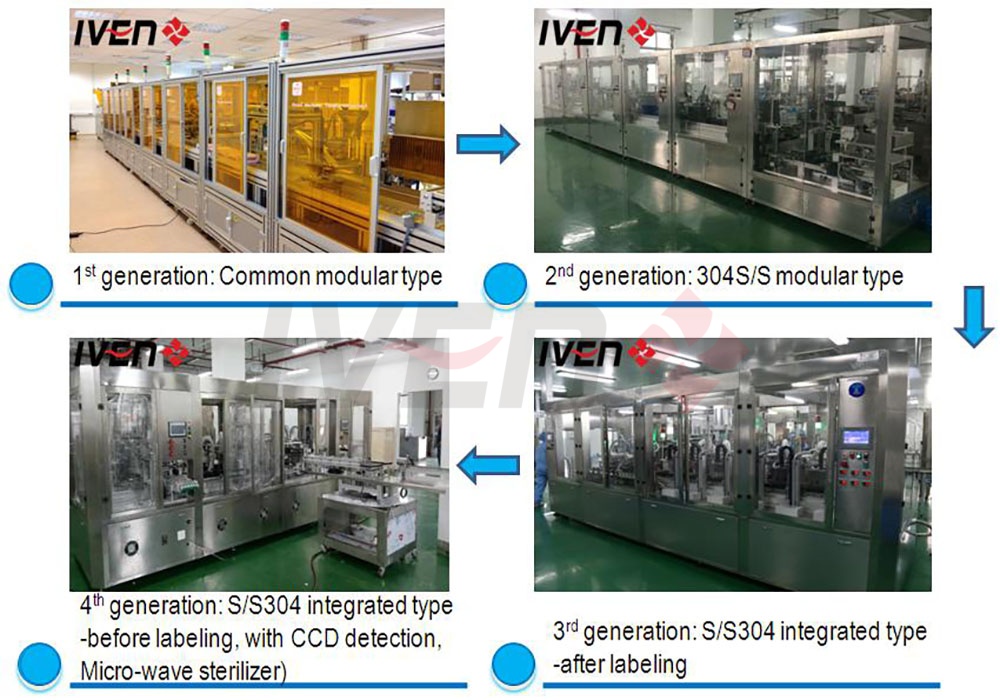

Based on the deep research of the US BD vacutainer, we adopted the most advanced vacuum blood collection tube production technology, in the past 15 years we developed 5 generations of the vacuum blood collection tube assembling line and supply the most advanced technology for vacuum blood collection tube turnkey plant.

5th generation: S/S 304 Combination type vacuum blood collection tube assembling line.

We have an intelligent R&D team, a very aggressive and elaborate technician team, and a very high-efficient and cooperative after-sales service team, we contributed all our efforts to the development of vacuum blood collection tube production machinery, thus we achieve the leading manufacture position in the field of vacuum blood collection tube assembling line and turnkey plant in China, and promoted China vacuum blood collection tube industry developed to a high level.

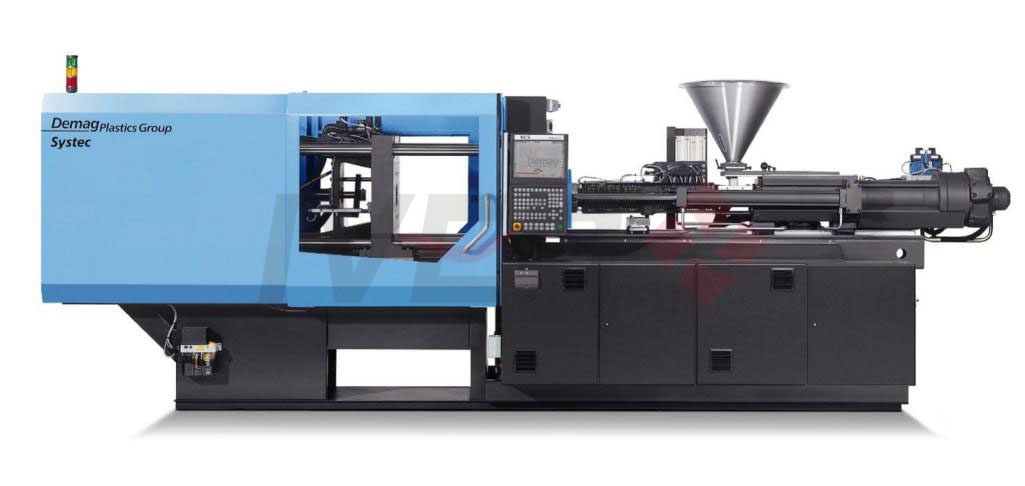

1.Injection molding machine for tubes and caps:

To inject the vacuum blood collection tubes and caps, we use Germany brand injection machine, to work with the NO.1 injection mold in China, to give the best quality of finished tubes and caps.

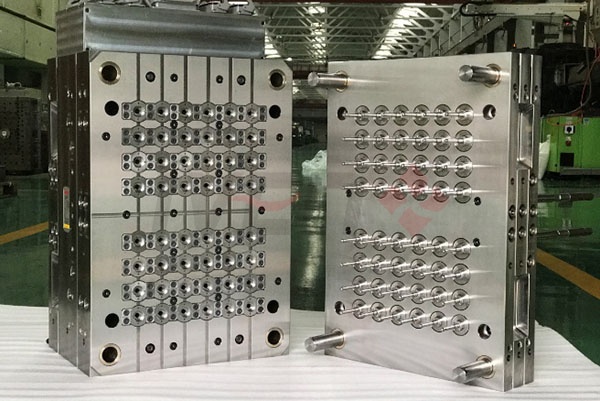

2.Injection mold for tubes and caps:

The molds adopt Husky hot runner, save material and keep good quality of products.

3.Vacuum blood collection tube assembling line:

The blood collection tube production line includes tube loading, Chemical dosing, drying, stoppering & capping, vacuuming, tray loading, etc. Easy & safe operation with individual PLC &HMI control, only need 2-3 workers can run the whole line well.

4.Packing line:

After vacuum blood collection tube assembling, it will be packed by shrink package machine, then put the finished products in the shipping carton. This process can be done manually or automatically.

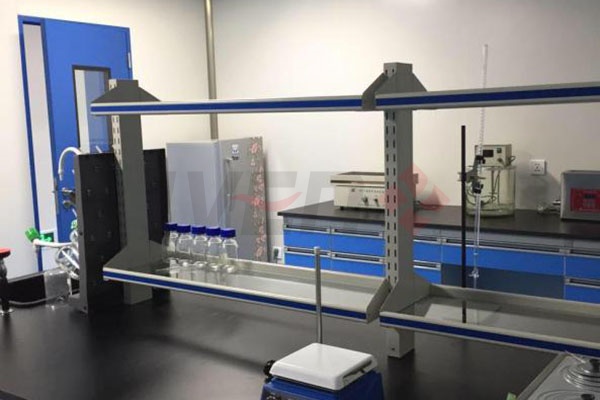

5.Clean room & HVAC:

It includes clean room wall panels, ceiling panels, windows, doors, flooring, lighting, air handling unit, HEPA filters, air ducts, alarming, auto control system etc. To keep the key IV solution production process protected under Class C + A environment.

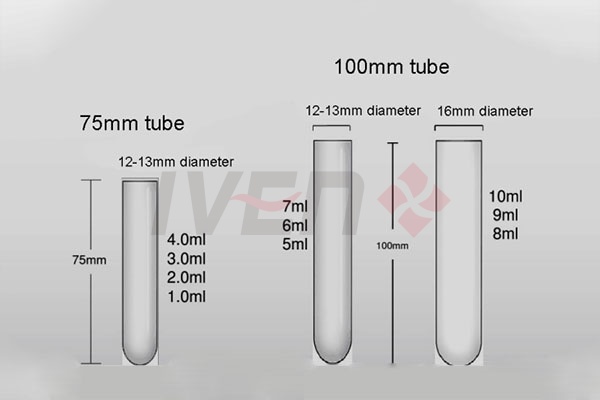

| Applicable Tubes | Ø13×75/100mm & Ø16×100mm PET tube(or glass tubes.) | ||

| Production Capacity | Coagulant:15000-18000 Pcs/H | ||

| Anticoagulant:15000-18000 Pcs/H | |||

| Sodium Citrate: 15000-20000 Pcs/H | |||

| Dosing Method &Accuracy | Coagulant | 5 nozzles, | ≤5% |

| Ceramic syringe pump | (Basic 20ul) | ||

| Anticoagulant | 5 nozzles, | ≤5% | |

| USA FMI metering pump | (Basic 20ul) | ||

| Sodium citrate | 5 nozzles, Ceramic syringe pump | ≤5% | |

| (Basic 100ul) | |||

| Drying Method | PTC heating way, equipped with high pressure fan | ||

| Cap Spec. | Upward Type | ||

| Applicable Form Tray | Interlace type and Rank type | ||

IVEN have a very professional technical and engineering team, our onsite training and after-sales support can give long term technical assurance for your NON-PVC IV fluid turnkey plant:

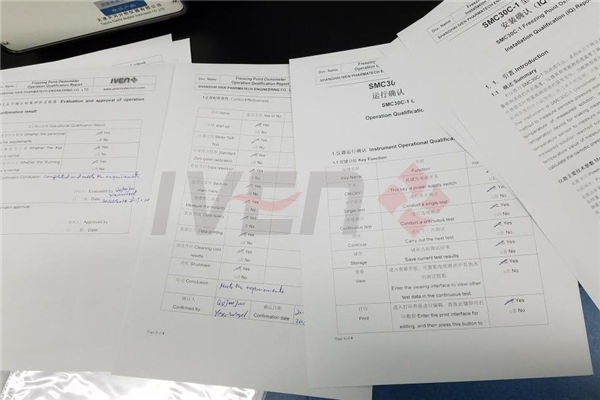

IVEN Full range of documentation can help you get GMP & FDA certificate for your IV fluid plant easily(Including IQ / OQ / PQ / DQ / FAT / SAT etc both in English and Chinese version):

IVEN profession and experience can help you finish whole IV solution turnkey plant in the shortest time and avoid all kinds of potential risks:

IVEN have a very professional technical and engineering team, our onsite training and after-sales support can give long term technical assurance for your NON-PVC IV fluid turnkey plant:

Till now, we’ve already provided hundreds sets of pharmaceutical equipment and medical equipment to more than 50 countries.

Meanwhile, we helped our customers to built 20+ pharmaceutical and medical turnkey plants in Uzbekistan, Tajikistan, Indonesia, Thailand, Saudi, Iraq, Nigeria, Uganda, Tanzania, Ethiopia, Myanmar etc, mainly for IV solution, injectable vials and ampoules. All these projects won our customers and their government high comments.

We also exported our IV solution production line to Germany.

Indonesia IV bottle turnkey plant

Vietnam IV bottle turnkey plant

Uzbekistan IV bottle turnkey plant

Thailand Injectable vial turnkey plant

Tajikistan IV bottle turnkey plant