Special Design for Blood Collection Tube Manufacturing Process Vacuum - Syringe Assembling Machine – IVEN

Special Design for Blood Collection Tube Manufacturing Process Vacuum - Syringe Assembling Machine – IVEN Detail:

Brief Introduction:

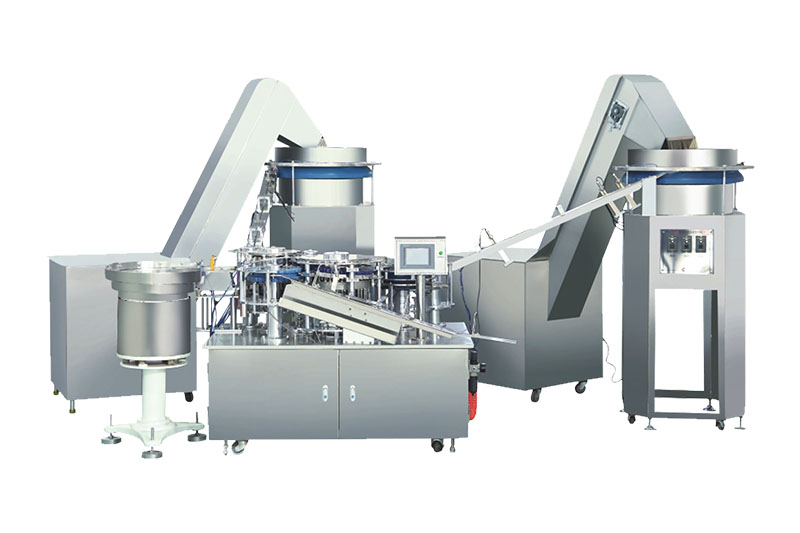

Our Syringe Assembling Machine is used for assembling syringe automatically. It can produce all kinds of syringes, including luer slip type, luer lock type, etc.

Our Syringe Assembling Machine adopts LCD display to display the feeding speed, and can adjust the assembly speed separately, with electronic counting. High efficiency, low power consumption, easy maintenance, stable operation, low noise, suitable for the GMP workshop.

Product Video

Product Description:

Our syringe assembling machine consists of feeding system and assembly mechanism.

Feeding system: feed 4 components of syringe (plunger/stopper/needle/barrel) to the assembly mechanism.

Feeding system are composed of feed bin and centrifugal feeder for barrel/plunger, hopper and feeder for needle/stopper.

Feeding system with photoelectric sensors, when assembling mechanism is full of products it will stop feeding, and when there is lack of products it will start working automatically.

Assembly Mechanism: assemble all parts of components together as a finished product. Usually, It completes 3 actions: action 1 – assemble plunger with rubber stopper; action 2 – assemble barrel with needle; action 3 – assemble plunger with stopper and barrel with needle.

Main Technical Parameters:

|

Model |

ZZ-001IV |

| Applicable Specification | 2ml~50ml |

| Production Capacity | 150-250pcs/min |

| Overall Dimension | 4200*3000*2100mm |

| Weight | 1500kgs |

| Power Supply | AC220V/3KW |

| Compressed Air Flow | 0.3m³/min |

Main Configuration List

|

No. |

Name |

Brand |

Remark |

|

1 |

Frequency converter | Mitsubishi (Japan) | |

|

2 |

Motor | Taizhou, China | |

|

3 |

Reducer | Hangzhou, China | |

|

4 |

Adjustable-speed motor | Mitsubishi (Japan) | |

|

5 |

Control system | Single chip microcomputer | |

|

6 |

Touch Screen | China | |

|

7 |

CCD vision sensor system | KEYENCE (Japan) | |

|

8 |

The housing material | SS 304, Plated metal | |

|

9 |

Dust cover | Aluminum profile |

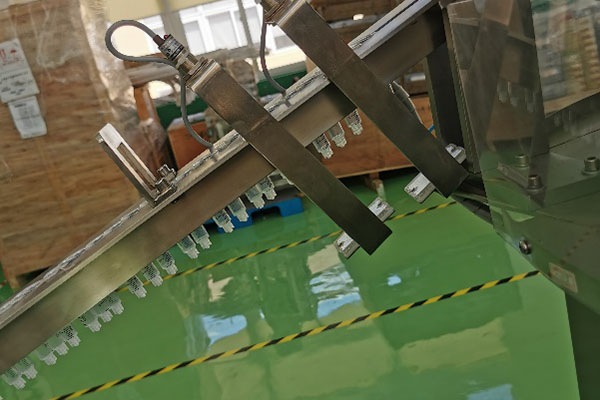

Product detail pictures:

Related Product Guide:

We also offer product sourcing and flight consolidation services. We've got our personal factory and sourcing office. We can easily present you with almost every style of merchandise linked to our merchandise range for Special Design for Blood Collection Tube Manufacturing Process Vacuum - Syringe Assembling Machine – IVEN , The product will supply to all over the world, such as: South Africa, Eindhoven, Hungary, In order to meet our market demands, we have paied more attention to the quality of our products and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!