Renewable Design for Disposable Syringe Factory - Automated Warehouse System – IVEN

Renewable Design for Disposable Syringe Factory - Automated Warehouse System – IVEN Detail:

Name of the System:

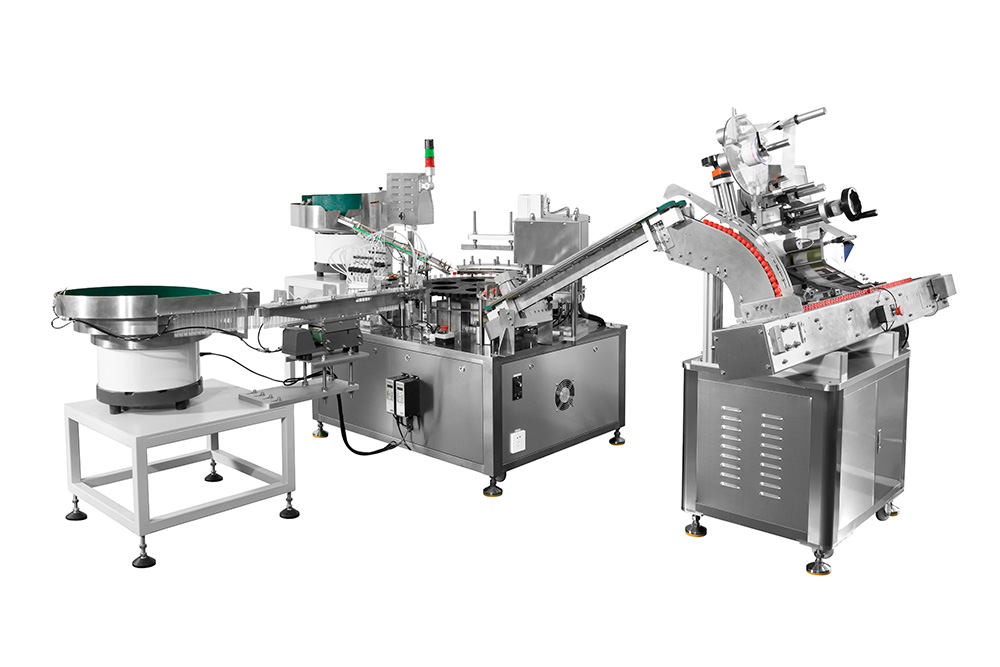

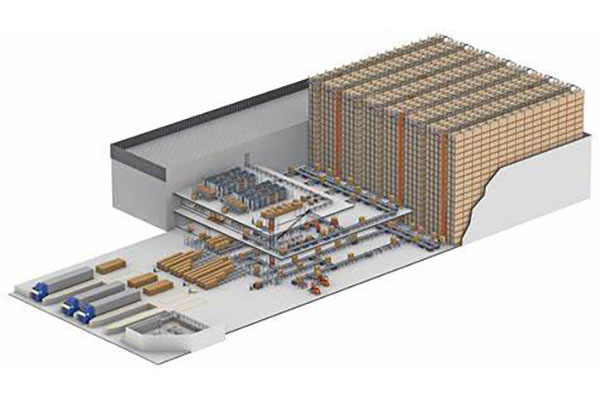

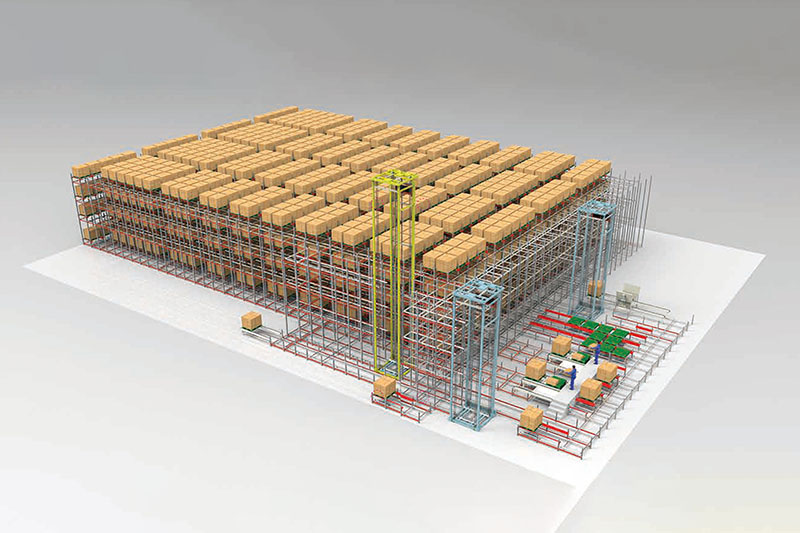

AS/RS (Automatic Storage Retrieval System)

Automated warehouse system

Product Video

Photo of the System:

Description of the System:

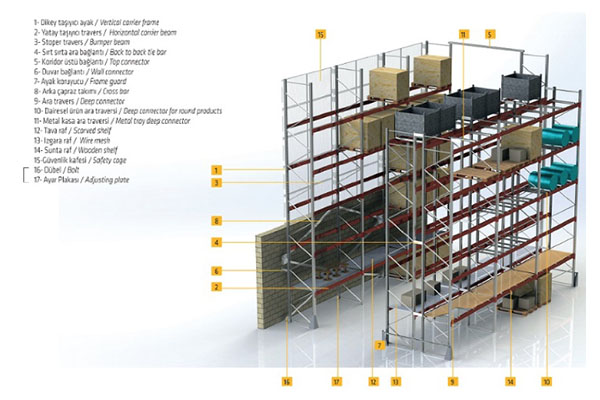

The AS/RS system usually contains several parts as Rack system, WMS software, WCS operation level part and etc.

It is widely adopted in many pharmaceutical and food production field.

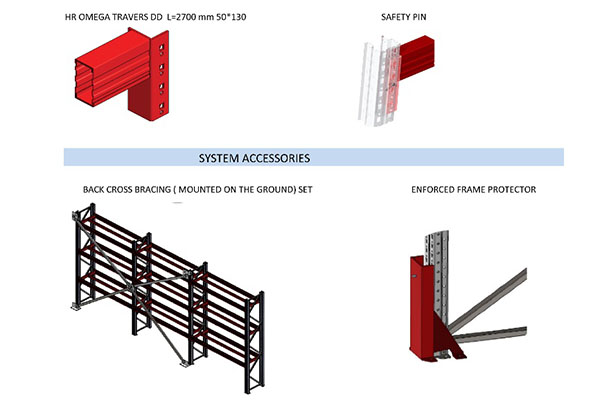

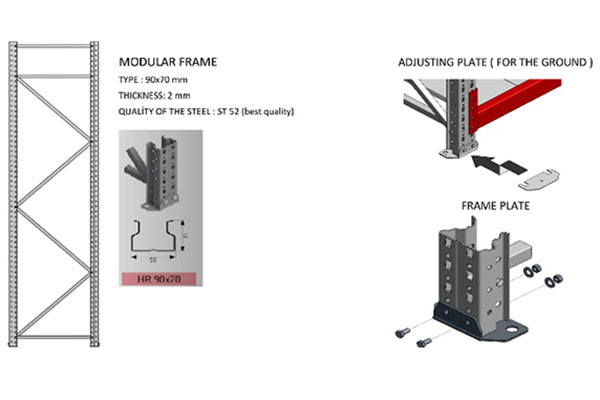

Rack system:

WMS:

A warehouse management system (WMS) is software and processes that allow organizations to control and administer warehouse operations from the time goods or materials enter a warehouse until they move out. Operations in a warehouse include inventory management, picking processes and auditing.

For example, a WMS can provide visibility into an organization’s inventory at any time and location, whether in a facility or in transit. It can also manage supply chain operations from the manufacturer or wholesaler to the warehouse, then to a retailer or distribution center. A WMS is often used alongside or integrated with a transportation management system (TMS) or an inventory management system.

Advantages:

-Although a WMS is complex and expensive to implement and run, organizations gain benefits that can justify the complexity and costs.

-Implementing a WMS can help an organization reduce labor costs, improve inventory accuracy, improve flexibility and responsiveness, decrease errors in picking and shipping goods, and improve customer service. Modern warehouse management systems operate with real-time data, allowing the organization to manage the most current information on activities like orders, shipments, receipts and any movement of goods.

WCS:

-Although a WMS is complex and expensive to implement and run, organizations gain benefits that can justify the complexity and costs.

-Implementing a WMS can help an organization reduce labor costs, improve inventory accuracy, improve flexibility and responsiveness, decrease errors in picking and shipping goods, and improve customer service. Modern warehouse management systems operate with real-time data, allowing the organization to manage the most current information on activities like orders, shipments, receipts and any movement of goods.

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Renewable Design for Disposable Syringe Factory - Automated Warehouse System – IVEN , The product will supply to all over the world, such as: Sudan, Slovakia, Mumbai, By adhering to the principle of human oriented, winning by quality, our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.