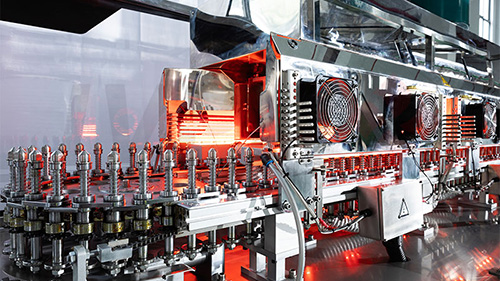

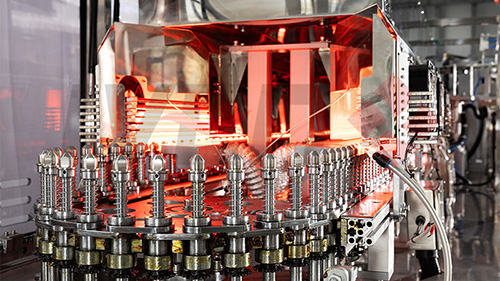

PP Bottle IV Solution Production Line

Automatic PP bottle IV solution production line includes 3 set equipment, Preform/Hanger Injection machine, Bottle blowing machine, Washing-Filling-Sealing machine. The production line has the feature of automatic, humanized and intelligent with stable performance and quick and simple maintenance. High production efficiency and low production cost, with high quality product which is the best choice for IV solution plastic bottle.

Preform/Hanger Injection machine + Bottle blowing machine + Washing-Filling-Sealing machine

| Item | Machine model | |||||

| CPS4 | CPS6 | CPS8 | CPS10 | CPS12 | ||

| Production capacity | 500ml | 4000BPH | 6000BPH | 8000BPH | 10000BPH | 12000BPH |

| Max bottle height | mm | 240 | 230 | |||

| Max preform height(with neck) | mm | 120 | 95 | |||

| Compressed air (m³/min) | 8-10bar | 3 | 3 | 4.2 | 4.2 | 4.5 |

| 20bar | 2.5 | 2.5 | 4.5 | 6.0 | 10-12 | |

| Chilled Water(m³/h) | 10°C(pressure: 3.5-4bar)8HP | 4 | 4 | 7.87 | 7.87 | 8-10 |

| Cooling Water | 25°C(pressure: 2.5-3bar) | 6 | 10 | 8 | 8 | 8-10 |

| Weight | T | 7.5 | 11 | 13.5 | 14 | 15 |

| Machine size(with Preform loading) | (L×W×H)(MM) | 6500*4300*3500 | 8892*4800*3400 | 9450*4337*3400 | 10730x4337x3400 | 12960×5477×3715 |

| Item | Machine model | ||||

| XGF(Q)/30/24/24 | XGF30/30/24/24 | XGF(Q)/36/30/36 | XGF(Q)/50/40/56 | ||

| Production capacity | 100ml | 7000BPH | 7000BPH | 9000BPH | 14000BPH |

| 500ml | 6000BPH | 6000BPH | 7200BPH | 12000BPH | |

| Applicable bottle size | ml | 50/100/250/500/1000 | |||

| Air consumption | 0.5-0.7Mpa | 3m3/min | 3m3/min | 3m3/min | 4-6m3/min |

| WFI consumption | 0.2-0.25Mpa | 1-1.5m3/h | |||

| Machine weight | T | 6 | 6.5 | 7 | 9 |

| Machine size | mm | 4.3*2.1*2.2 | 5.76*2.1*2.2 | 4.47*1.9*2.2 | 6.6*3.3*2.2 |

| Power consumption | Main motor | 4 | 4 | 4 | 4 |

| Capping oscillator | 0.5 | 0.5 |

0.5 |

0.5*2 | |

| Ionic air | 0.25*6 | 0.25*5 |

0.25*6 |

0.25*9 | |

| Conveyor motor | 0.37*2 | 0.37*2 |

0.37*2 |

0.37*3 | |

| Heating plate | 6*2 | 6*2 |

6*2 |

8*3 | |

Send your message to us:

Write your message here and send it to us