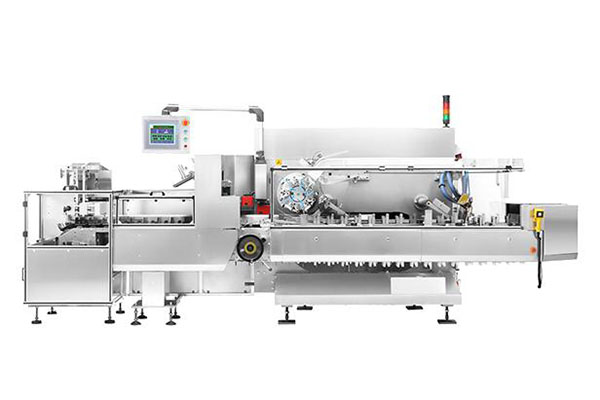

Pharmaceutical and Medical Automatic Packaging System

It mainly includes the steps of automatic box opening, packing,box sealing. Box opening and sealing are relatively simple, the main technical core is packing. Choose the appropriate packaging method according to the packaging material of the product, such as plastic bottles, soft bags, glass bottles, medicine boxes, as well as the placement direction and position in the carton. For example, according to the placement position, after sorting bags and bottles, the robot will grab it and put it into an opening carton. You can choose instructions inserting, certificates inserting, partition placement, weighing and rejecting and other functions as optional, and then follow the carton sealing machine and palletizer are used in line.

The secondary packing production line for pharmaceutical and medical meets with the high level capacity and realize automatic transportation and automatic sealing.

Comply with GMP and other international standards and design requirements.

For different packing products equipped with different packing grip.

The whole packaging process is transparent and visible.

Production process monitoring system ensures smooth maintenance of equipment.

Super long carton storage bit, can store more than 100 cartons.

Full servo control.

With industrial robots suitable for all kinds secondary packing production line in pharmaceutical and medical productions.

Step 1: Cartoning machine

1.Product feeding into the cartoning machine

2.Automatically carton box unfolding

3.Feeding the products into the cartons, with leaflets

4.Sealing the carton

Step 2: Big case cartoning machine

1.The products in cartons feeding into this big case cartoning machine

2.Big case unfolding

3.Feeding products into big cases one by one or layer by layer

4.Seal the cases

5.Weighing

6.Labeling

Step 3: Automatic palletizing unit

1.The cases transfered via the auto logistic unit to the automatic palletizing robot station

2.Palletizing automatically one by one , which palletizing designed meet the users personalized needs

3.After palletizing, the cases will be delivered into warehouse by manual way or automatically

|

Name |

Specification |

Qty |

Unit |

Remark |

| The carton conveying line speed |

8 meters/min; |

|

|

|

| Bottle/bags etc. Conveying speed: |

24-48 meters/min, variable frequency adjustment. |

|

|

|

| The carton forming speed |

10 cartons/min |

|

|

|

| The carton transportation height |

700mm |

|

|

|

| The equipment operation height |

Up to 2800mm in the packaging area |

|

|

|

|

Apply for products sizes |

One size with machine |

|

|

Extra size needs changing parts |

|

Servo lane divider |

Servo motor |

1 |

Set |

|

|

Regular conveyor |

Servo motor |

1 |

Set |

|

|

Box opening machine |

|

1 |

Set |

|

|

Turn electric drum line |

|

1 |

Set |

|

|

Floor plate feeder |

Pneumatic |

1 |

Set |

|

|

Roofer |

Pneumatic |

1 |

Set |

|

|

Electric drum line |

10 meter |

3 |

Pcs |

10 meter |

|

Robot packaging |

35kg |

1 |

|

|

|

Quick change disk assembly |

|

2 |

Set |

250ml 500ml |

|

Hand claw assembly |

|

2 |

Set |

|

|

Port guide assembly |

|

2 |

Set |

|

|

Empty drum roller conveyor assembly |

With blocker 2 sets |

2 |

Set |

|

|

Manual certification machine (optional) |

|

1 |

Set |

|

|

Weighing machine (optional) |

Toledo |

1 |

Set |

With exclusion |

|

Sealing machine |

|

1 |

Set |

|

|

Spray code belt line (optional) |

|

1 |

Set |

|

|

Codeline |

L2500, 1 blocker |

1 |

Pcs |

|

|

Palletizing robot (optional) |

75kg |

1 |

Set |

|

|

Hand claw assembly |

|

1 |

Set |

|

|

Raster security fence |

|

|

|

|

|

Electronic control system |

|

1 |

Set |

Packaging |