OEM Customized Pharma Machinery Supplier - Prefilled Syringe Machine – IVEN

OEM Customized Pharma Machinery Supplier - Prefilled Syringe Machine – IVEN Detail:

What is the prefilled Syringe?

Prefilled syringe is a new type of drug packaging developed in 1990s. After more than 30 years of popularization and use, it has played a good role in preventing the spread of infectious diseases and the development of medical treatment. Prefilled syringes are mainly used for packaging and storage of high-grade drugs and are directly used for injection or surgical ophthalmology, otology, orthopedics, etc.

At present, the first generation of all glass syringe has been less used. The second generation disposable sterile plastic syringe is widely used in the world. Although it has the advantages of low cost and convenient use, it also has its own defects, such as acid and alkali resistance, recycling and environmental pollution. Therefore, developed countries and regions have gradually promoted the use of the third generation of pre filled syringes. A kind of the pre filling syringe has the functions of storing medicine and ordinary injection at the same time, and uses the materials with good compatibility and stability. It is not only safe and reliable, but also reduces the labor and cost from production to use to the greatest extent compared with the traditional “medicine bottle + syringe”, which brings many advantages to pharmaceutical enterprises and clinical use. At present, more and more pharmaceutical enterprises have adopted and applied in clinical practice. In the next few years, it will become the main packaging method of drugs, and gradually replace the status of ordinary syringes.

Product Video

What is the Prefilled Syringe Characteristics?

As a new type of drug packaging, prefilled syringe is characterized by :

(1)Using high quality glass and rubber components, which has good compatibility with drugs and can ensure the stability of packaged drugs ;

(2)Reducing the waste caused by the adsorption of drugs during storage and transfer, especially for expensive biochemical preparations ;

(3)Avoiding repeated suction after the use of diluents and reducing the chance of secondary contamination ;

(4)Using filling machine to fill the liquid quantitatively, which is more accurate than the manual suction of medical staff ;

(5)Indicating the name of the drug directly on the injection container, which is not easy to make clinic; If the label is easy to peel off, it is also helpful to preserve the information of drug use in patients .

(6)It is easy to operate and saves half the time in clinic than using ampoules, which is especially suitable for emergency patients.

What is the range of application of the Prefilled Syringe ?

(1)injection use: take out the prefilled syringe supplied by pharmaceutical enterprises, remove the packaging and inject directly. The injection method is the same as that of ordinary syringe.

(2)After removing the packaging, the matching flushing needle is installed on the cone head, and the washing in surgical operation can be carried out.

Detailed description

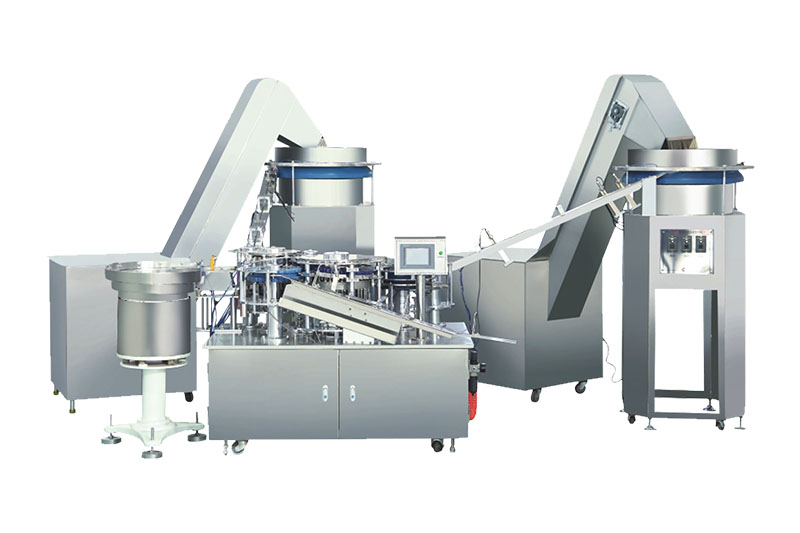

There are different types of prefilled syringe machine from IVEN Pharmatech, the prefilled syringe machines identified by the production process and capacity .

Prefilled syringe feeding before filling can be done by both automatic way and manual way.

After the prefilled syringe fed into machine, it is filling and sealing , then the prefilled syringe also could be light inspected and labelled online, by which the automatic plungering is followed. Until now the prefilled syringe can be delivered into sterilization and blister packing machine and cartoning machine for further packing .

The main capacities of the prefilled syringe is 300pcs/hr and 3000pcs/hr.

The prefilled syringe machine could produce the syringe volumes like 0.5ml/1ml/2ml/3ml/5ml/10ml/20ml etc.

Introduction of product advantages

The prefilled syringe machine is compatible to the presterilized syringes, and all customized products. It is equipped with Germany original high precision linear rail and free of maintenance. Driven with 2 sets of servo motors made by Japan YASUKAWA.

Vacuum plugging , avoiding micro particles from the friction if vibrator is used for rubber stoppers.Vacuum sensors also sourced from Japaness brand. Vacuuming is adjustable in stepless way.

Print-out of process parameters, original data is stored.

All contact parts material is AISI 316L and pharmaceutical silicon rubber.

Touch screen displaying all working status includingreal time vacuum pressure, nitrogen pressure , air pressure, multi languages are available.

AISI 316L or high precision ceramic rotation pistion pumps are driven with servo motors. Only set-up on touch screen for automatic accurate correction. Each piston pump can be tuned without any tool.

Tech Parameters

| Filling Volume | 0.5ml, 1ml, 1-3ml, 5ml, 10ml, 20ml |

| Number of Filling Head | 10 Sets |

| Capacity | 2,400-6,00 Syringes/Hour |

| Y Travel Distance | 300 mm |

| Nitrogen | 1Kg/cm2, 0.1m3/min 0.25 |

| Compressed Air | 6kg/cm2, 0.15m3/min |

| Power Supply | 3P 380V/220V 50-60Hz 3.5KW |

| Dimension | 1400(L)x1000(W)x2200mm(H) |

| Weight | 750Kg |

Product detail pictures:

Related Product Guide:

Our firm sticks to the basic principle of Quality is the life of your company, and status will be the soul of it for OEM Customized Pharma Machinery Supplier - Prefilled Syringe Machine – IVEN , The product will supply to all over the world, such as: Brunei, Chile, Gabon, Why we can do these? Because: A, We are honest and reliable. Our products have high quality, attractive price, sufficient supply capacity and perfect service. B, Our geographical position has a big advantage . C, Various types: Welcome your inquiry, It will be highly appreciated.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.