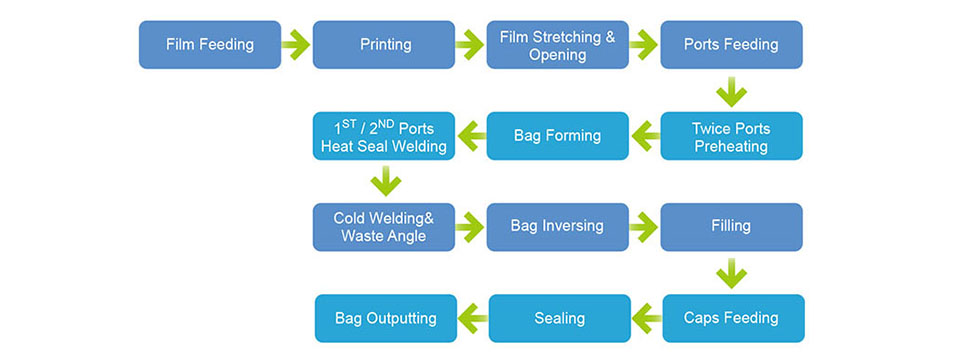

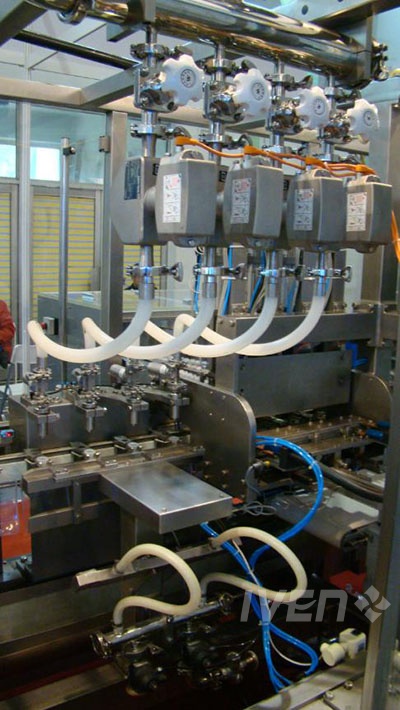

Non-PVC Soft Bag Production Line

It can be applied to 50-5000ml Non-PVC soft bag for general solution, special solution, dialysis solution, parenteral nutrition, antibiotics, irrigation and disinfectant solution etc.

| Item | Main Content | ||||||||

| Model | SRD1A | SRD2A | SRS2A | SRD3A | SRD4A | SRS4A | SRD6A | SRD12A | |

| Actual Production Capacity | 100ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | 10000 |

| 250ML | 1000 | 2200 | 2200 | 3200 | 4000 | 4000 | 5500 | 10000 | |

| 500ML | 900 | 2000 | 2000 | 2800 | 3600 | 3600 | 5000 | 8000 | |

| 1000ML | 800 | 1600 | 1600 | 2200 | 3000 | 3000 | 4500 | 7500 | |

| Power Source | 3 Phase 380V 50Hz | ||||||||

| Power | 8KW | 22KW | 22KW | 26KW | 32KW | 28KW | 32KW | 60KW | |

| Compressed Air Pressure | Dry and oil-free compressed air, the cleaness is 5um,the pressure is over 0.6Mpa.The machine will automatically warn and stop when the pressure is too low | ||||||||

| Compressed Air Consumption | 1000L/mim | 2000L/mim | 2200L/mim | 2500L/mim | 3000L/mim | 3800L/mim | 4000L/mim | 7000L/mim | |

| Clean Air Pressure | The pressure of clean compressed air is over 0.4Mpa, the cleaness is 0.22um | ||||||||

| Clean Air Consumption | 500L/min | 800L/min | 600L/min | 900L/min | 1000L/min | 1000L/min | 1200L/min | 2000L/min | |

| Cooling Water Pressure | >0.5kgf/cm2 (50kpa) | ||||||||

| Cooling Water Consumption | 100L/H | 300L/H | 100L/H | 350L/H | 500L/H | 250L/H | 400L/H | 800L/H | |

| Nitrogen Consumption | According to the customer's special requirements, we can use the nitrogen to protect the machine, the pressure is 0.6Mpa. The consumption is less than 45L/min | ||||||||

| Running Noise | <75dB | ||||||||

| Room requirements | Temperature of the environment should ≤26℃, the humidity: 45%-65%, Max. humidity should less than 85% | ||||||||

| Overall Size | 3.26x2.0x2.1m | 4.72x2.6x2.1m | 8x2.97x2.1m | 5.52x2.7x2.1m | 6.92x2.6x2.1m | 11.8x2.97x2.1m | 8.97x2.7x2.25m | 8.97x4.65x2.25m | |

| Weight | 3T | 4T | 6T | 5T | 6T | 10T | 8T | 12T | |

*** Note: As products are constantly updated, please contact us for latest specifications. ***

Send your message to us:

Write your message here and send it to us