Ampoule filling machines are essential equipment in the pharmaceutical and healthcare industries for accurately and efficiently filling and sealing ampoules. These machines are designed to handle the fragile nature of ampoules and ensure accurate filling of liquid medications or solutions. Understanding the principles behind ampoule filling machines is crucial to understanding their functionality and importance in pharmaceutical manufacturing.

Ampoule Filling Lines are a type of pharmaceutical machinery that is used for filling and sealing of ampules. These devices are compact and maintain consistency during the filling and sealing processes. Ampoule Filling and Sealing Machine or ampoule filler machine perform filling sealing built on advanced technology to fulfil the requirement in Pharmaceutical Filling Industry. Ampoules are filed with liquid then purged with nitrogen gas and finally sealed using combustible gases. Machine is having specially designed filling pump for precise filling of liquid with neck centering during filling operation. Ampoule are sealed immediately after filling the liquid in order to avoid contamination. They are also safe for use in the storage and transportation of liquid and powdered medicines.

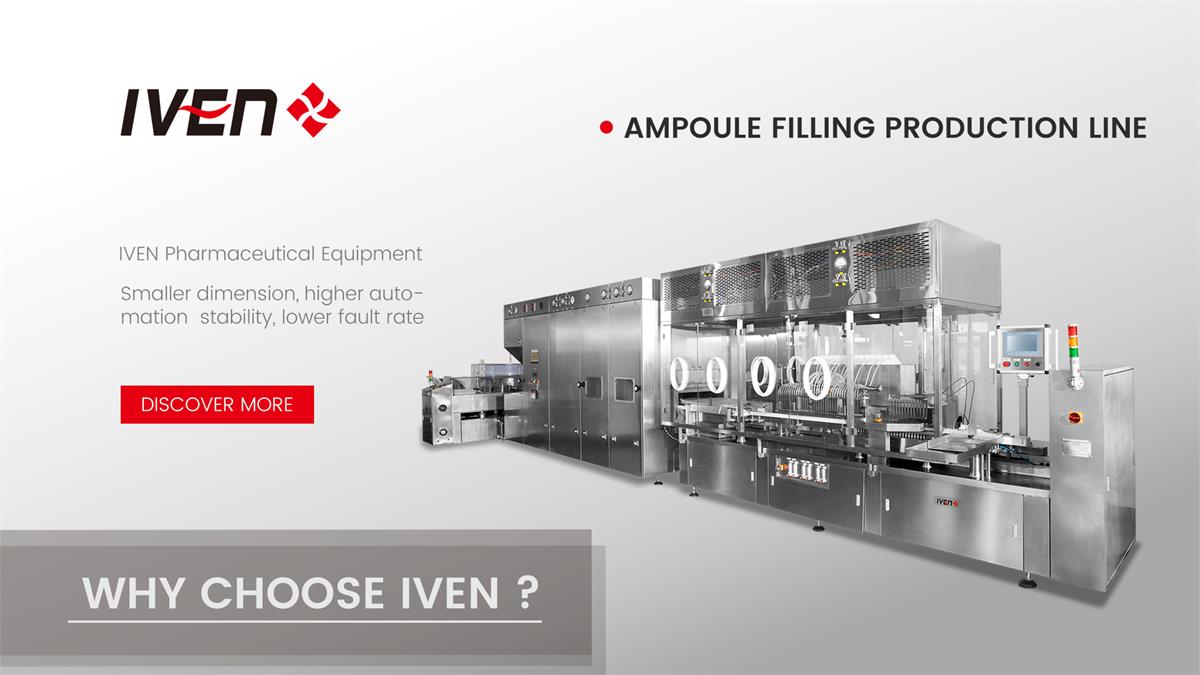

The Ampoule filling production line includes vertical ultrasonic washing machine, RSM sterilizing drying machine and AGF filling and sealing machine. It is divided into washing zone, sterilizing zone, filling and sealing zone. This compact line can work together as well as independently. Compared with other manufacturers, IVEN'S equipment has unique features, including overall dimension smaller, higher automation & stability, lower fault rate and maintenance cost, and etc.

The principle of the ampoule filling machine is to accurately measure liquid and fill it into individual ampoules. The machine operates with a volumetric or syringe filling mechanism, ensuring that the exact amount of product is dispensed into each ampoule. This is achieved through a series of carefully calibrated processes that include precise measurement and transfer of the liquid medication.

The functionality of an ampoule filling machine is based on several key components and processes. First, the ampoules are loaded into the machine's feeding system and then transported to the filling station. At the filling station, a filling mechanism such as a piston or peristaltic pump is used to dispense the precise volume of liquid into each ampoule. The filled ampoules are then moved to the sealing station where they are hermetically sealed to ensure the integrity of the product.

One of the basic principles of ampoule filling machines is the need for a sterile and contamination-free environment. The machines are equipped with advanced features such as laminar air flow, sterilization system and Clean in Place (CIP) functionality to maintain the highest level of hygiene and product safety. This is critical in pharmaceutical manufacturing, where maintaining product purity and sterility is critical.

Another principle that governs the operation of ampoule filling machines is the need for precision and accuracy. Liquid medications must be dosed and filled with extreme precision to ensure each ampoule contains the correct dose. This is achieved through the use of advanced control systems and sensors that monitor and regulate the filling process to minimize variation and ensure consistency.

Furthermore, the principle of versatility is an integral part of ampoule filling machines. These machines are designed to accommodate a variety of ampoule sizes and types, allowing for flexibility in production. Whether standard ampoules, vials or cartridges, the machine can be adapted to handle different formats, making it suitable for a variety of pharmaceutical applications.

In summary, the principles of precision, sterility and versatility underpin the functionality of ampoule filling machines. These machines play a key role in pharmaceutical manufacturing, ensuring accurate dosing and filling of liquid medicines into ampoules while maintaining the highest hygiene standards and product integrity. Understanding the principles behind ampoule filling machines is crucial to understanding their importance in pharmaceutical production and the healthcare industry as a whole.

Post time: Aug-16-2024