In the biotechnology and biopharmaceutical fields, the terms "bioreactor" and "biofermenter" are often used interchangeably, but they refer to different systems with specific functions and applications. Understanding the differences between these two types of equipment is essential for professionals in the field, especially when designing and manufacturing systems that meet strict regulatory standards.

Defining Terms

Bioreactor is a broad term that covers any container in which a biological reaction occurs. This can include processes as diverse as fermentation, cell culture, and enzyme reactions. Bioreactors can be designed for aerobic or anaerobic conditions and can support a wide range of organisms, including bacteria, yeast, and mammalian cells. They are equipped with a variety of temperature, pH, oxygen level, and agitation controls to optimize growth conditions for the cultured microorganisms or cells.

A biofermenter, on the other hand, is a specific type of bioreactor that is primarily used in fermentation processes. Fermentation is a metabolic process that uses microorganisms, most commonly yeast or bacteria, to convert sugars into acids, gases, or alcohol. Biofermenters are designed to create an environment that is conducive to the growth of these microorganisms, thereby producing a variety of bioproducts such as ethanol, organic acids, and pharmaceuticals.

Main Differences

Function:

Bioreactors can be used for a variety of bioprocesses, including cell culture and enzyme reactions, while fermenters are specifically designed for fermentation processes.

Design Specifications:

Biofermenters are often designed with specific features to meet the needs of the fermenting organisms. For example, they may include features such as baffles to improve mixing, specific aeration systems for aerobic fermentation, and temperature control systems to maintain optimal growth conditions.

Application:

Bioreactors are highly versatile and can be used for a variety of applications in different industries, including pharmaceuticals, food and beverages, and environmental biotechnology. In contrast, fermenters are primarily used in industries that produce fermentation products, such as winemaking, brewing, and biofuel production.

Scale:

Both bioreactors and fermenters can be designed to different scales, from laboratory research to industrial production. However, fermenters usually have a larger capacity to accommodate the large amounts of product typically produced during the fermentation process.

The role of GMP and ASME-BPE in fermenter design

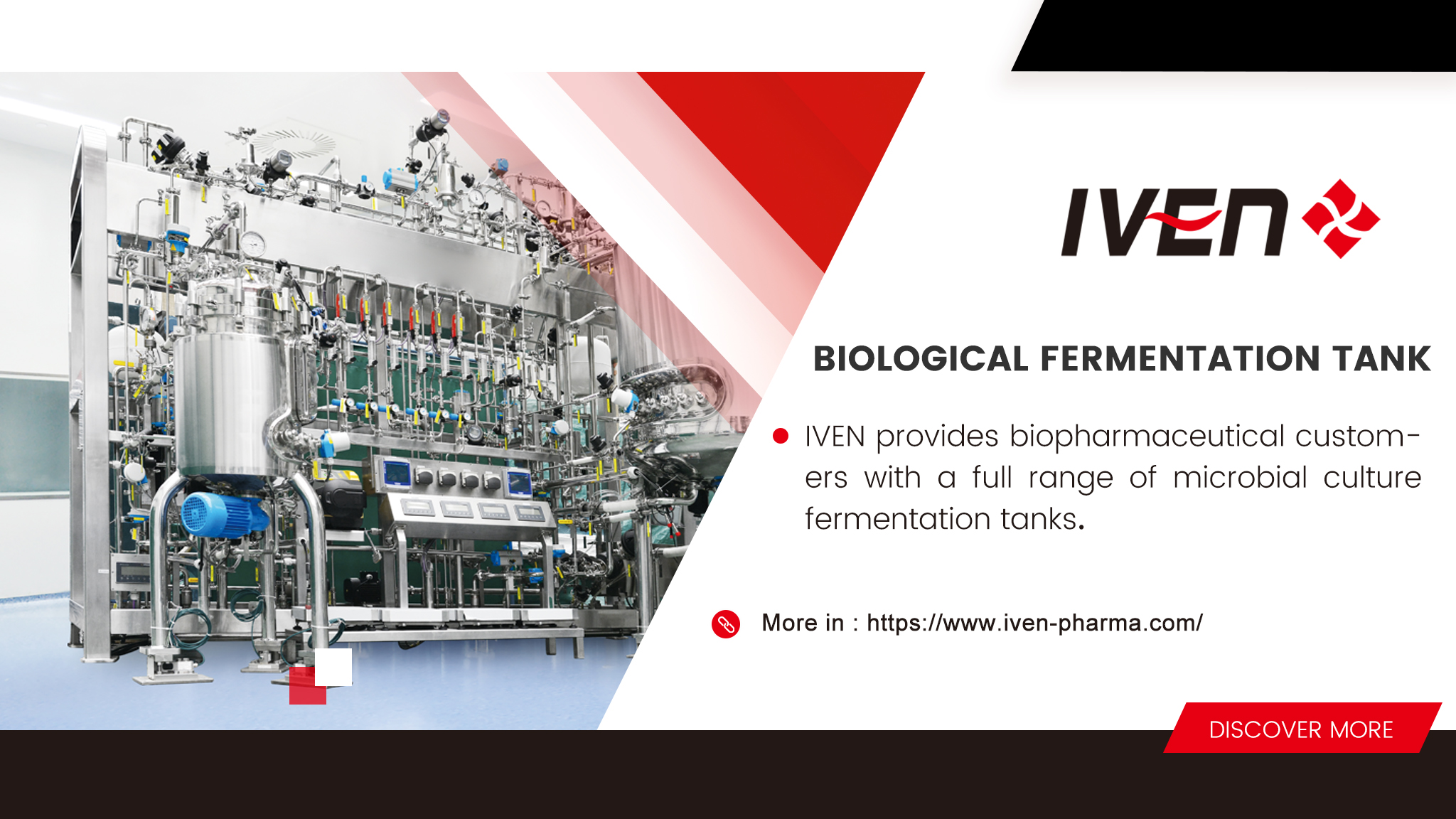

Compliance with regulatory standards is critical when it comes to the design and manufacture of bio-fermenters. At IVEN, we ensure that our fermenters are designed and manufactured in strict compliance with Good Manufacturing Practice (GMP) regulations and ASME-BPE (American Society of Mechanical Engineers - Bioprocessing Equipment) requirements. This commitment to quality and safety is critical to our biopharmaceutical customers who rely on our equipment for microbial culture fermentation.

Our fermentation tanks feature professional, user-friendly and modular designs that can be easily integrated into existing systems. We offer vessels that comply with various national pressure vessel standards, including ASME-U, GB150 and PED (Pressure Equipment Directive). This versatility ensures that our tanks can accommodate a wide range of applications and regulatory requirements.

Customization and Versatility

At IVEN, we understand that each biopharmaceutical customer has unique needs. That's why we offer a full range of fermenters for microbial cultivation, from laboratory R&D to pilot and industrial production. Our fermenters can be customized to specific requirements, including capacity, ranging from 5 liters to 30 kiloliters. This flexibility allows us to meet the needs of highly aerobic bacteria, such as Escherichia coli and Pichia pastoris, which are commonly used in biopharmaceutical production.

In summary, while both bioreactors and biofermenters play a vital role in the field of biotechnology, they are used for different purposes and are designed with different functions in mind. Understanding these differences is essential to choosing the right equipment for a specific application. At IVEN, we are committed to providing high-quality fermenters that meet the stringent requirements of the biopharmaceutical industry, ensuring that our customers can achieve the best results in their microbial cultivation processes. Whether you are in the early stages of research or scaling up industrial production, our expertise and customizable solutions can help you confidently navigate the complexities of bioprocessing.

Post time: Nov-14-2024