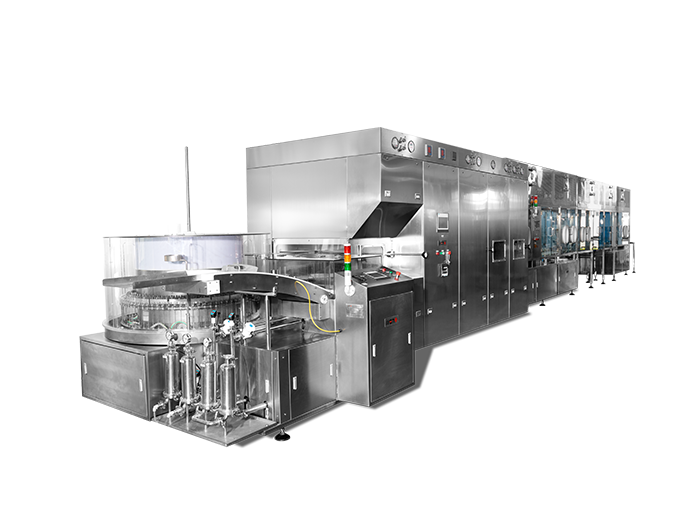

Vial Filling Machines in the Pharmaceutical

The vial filling machines is extensively used in the pharmaceutical industry to fill vials with medicinal ingredients. These highly durable machines are designed to perform the precise operation of expeditious vial filling. Vial filling machines also contain multiple filling heads that help them to achieve a higher filling rate and increased productivity to meet the demands of the pharmaceutical industry. There are many variants of vial-filling machines suitable for different applications in the pharmaceutical industry.

Vial Filling Machine Working Principle

The vial filling machine contains the SS slat conveyor for the effortless moving of the vials on the filling machine. From the conveyor belt, the empty sterilized vials are then transferred to the filling station, where the required pharmaceutical ingredients are filled in precise quantities. The filling stations contain multiple heads or nozzles that enable faster vial filling without waste. The number of filling heads from 2 to 20 could be customized as per the manufacturing requirement. The vials get precisely filled by the filling heads, after which the filled vials get transferred to the next station on the filling line. The machine maintains consistent sterility throughout the filling operations. At the next station, stoppers are placed over the head of the vials. This ensures that h sterility and integrity of the components s preserved. During the filling process, it is crucial to ensure that the pharmaceutical ingredients and vials are free of contaminants. Any disturbance with the chemical composition of the components could jeopardise the entire batch of filled vials and may even result in the rejection of the whole batch. The stoppers are then capped and sealed before going to the labeling station.

Types of Vial Filling Machines

It is prudent to understand different types of vial filling machines available and their design, application and working process. In below we are describing different types of vial filling machines with information thereof:

Vial Filling Machine

The pharmaceutical vial filling machine used in the pharmaceutical industry is also called the injectable vial filling machine and includes the vial filler and the rubber stoppers. These automatic vial-filling machines ensure consistency in volume, reduce product losses, and comes with a built-in quality control system for real-time volume checking of the vials. Pharmaceutical vial-filling machines are utilized in both sterile and non-sterile applications.

Vial Liquid Filling Machine

The vial liquid filling machine consists of the main machine, unscrambler, conveyor, stopper feeding bowl and scrambler. The conveyor belt transfers the vials towards the filling station, where the liquid contents are filled into the machine. Vial liquid filling machines fill liquids or fluids of various viscosities into the vials. These machines are widely used in the pharmaceutical industry to ensure the precise filling of the vials. The vials liquid filling machine works on the diving nozzle and volumetric principle, which provides sterile and precision filling operations.

Vial Powder Filling Machine

The vial powder filling machine consists of the washing, sterilizing, filling, sealing and labeling operations. All the equipment is aligned on the filling line to ensure continuous production of the vials for the pharmaceutical industry. The automatic vial powder filling machine is crucial in the pharmaceutical industry because that helps fill granules or powder into the vials.

Injectable Liquid Filling Machine

The liquid filling line or machine functions under high pressure. Therefore, it could also be classified as liquid pressure filling. In this process, the liquid injectable flows into the storage bottle depending on the weight when the pressure in the fluid reservoir becomes equal to the air pressure in the bottle.

The injectable liquid filling lines are easy to operate and fill the precise amount of liquid into bottles, containers or gallons. The filling mechanism built into the machine allows it to adjust the filling rate and quantity per bottle size or container without replacing any components. These machines are equipped with sensors that can automatically stop the process without any bottle on the belt.

Post time: Nov-20-2024