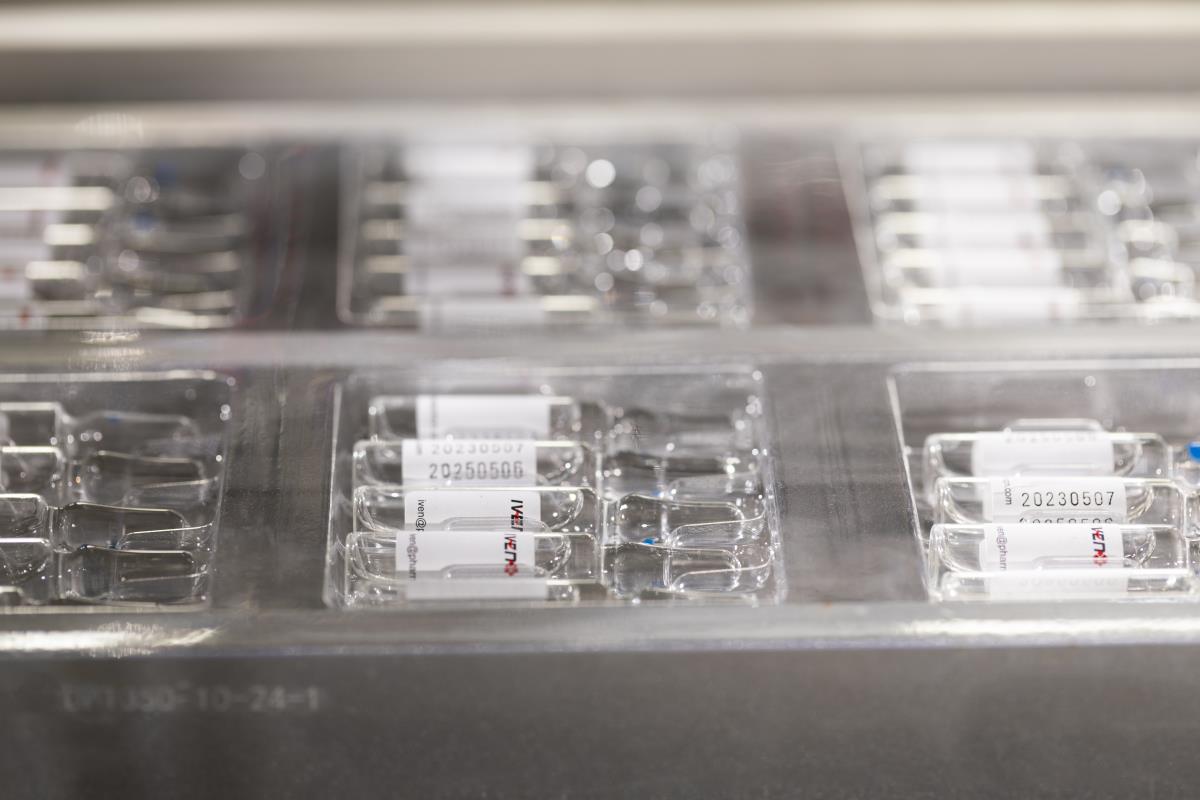

In the world of packaging, efficiency and protection are crucial, especially in industries such as pharmaceuticals, food and consumer goods. One of the most effective solutions for packaging products is blister packaging. A blister pack is a preformed plastic package consisting of a cavity or pocket made of a formable mesh (usually plastic) and sealed with a backing material (usually aluminum or cardboard).

Blister packaging is widely used to package tablets, capsules and other small items, making it a staple in the pharmaceutical industry. They are also widely used to package consumer products such as batteries, toys and electronics. Blister packs are designed to easily dispense individual units, improving user convenience and product visibility.

What are the advantages of blister packaging?

Blister packaging offers numerous advantages that make it the first choice for manufacturers and consumers alike. One of the main benefits is the protection they provide. The sealed environment of a blister pack helps protect products from moisture, light and air, which can degrade the quality of sensitive items, especially pharmaceuticals. This protective feature extends the shelf life of the product, ensuring it is effective and safe to consume.

Another significant advantage of blister packaging is its tamper-proof design. The sealing process creates a barrier that, if breached, indicates that the product has been accessed. This is particularly important for the pharmaceutical industry, where consumer safety is a top priority. Additionally, blister packs are lightweight and compact, which reduces shipping costs and makes storage easier.

Blister packaging also improves user convenience. They provide easy access to individual doses or items, reducing the risk of overdose or misuse. The product inside the blister pack is clearly visible, allowing consumers to quickly identify the contents, which is particularly beneficial in a pharmacy environment. Additionally, the design can be customized to include brand and product information, making it an effective marketing tool.

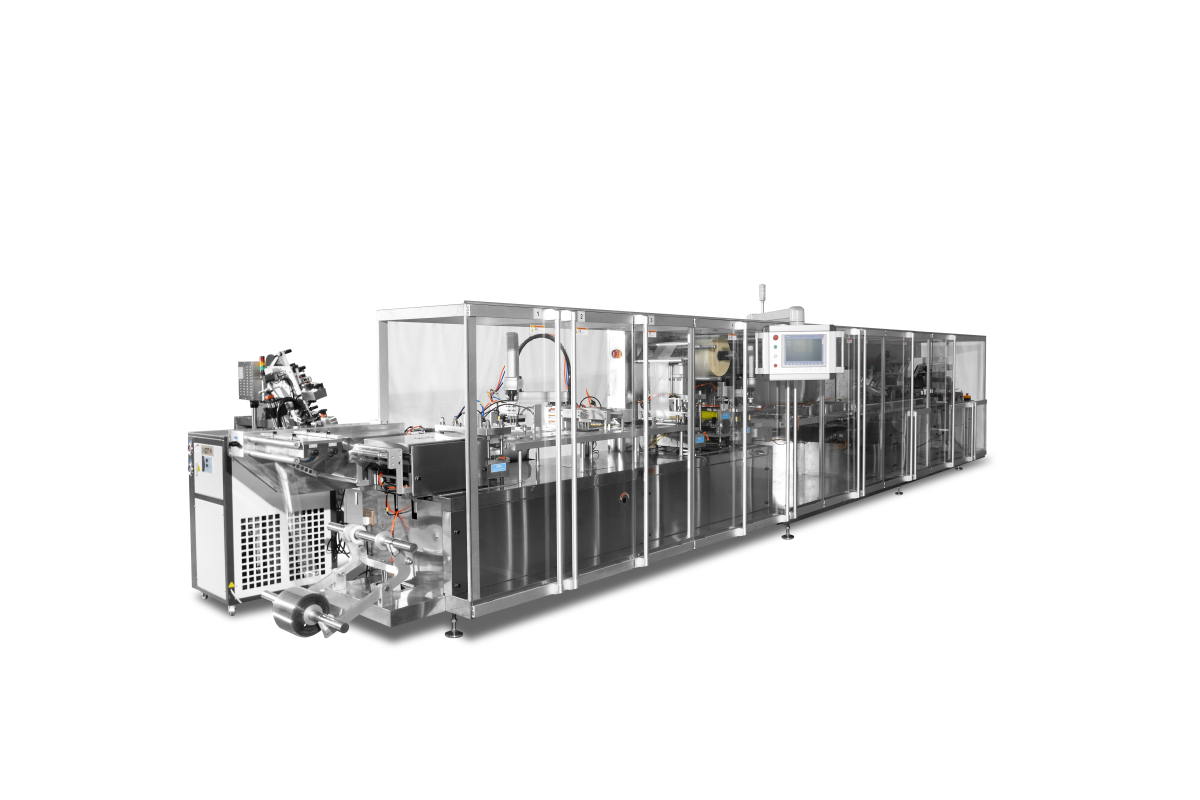

What is a blister packaging machine?

Blister packaging machine is an essential equipment in blister packaging production. The machine automates the blister pack making process, which includes several key steps: forming, feeding, sealing, embossing, perforating and punching. By streamlining these processes, blister packaging machines increase production efficiency and consistency.

Blister packaging machines come in two main designs: rotary and platen. The rotary blister packaging machine adopts the continuous motion principle, and the blister forming, filling and sealing processes are performed in a circular motion. This design is ideal for high-speed production and is often used in large-scale manufacturing environments. The rotary machine can handle blisters of various sizes and shapes, making them suitable for different products.

Platen blister packaging machines, on the other hand, operate on a stop-and-go basis. This design is typically used for smaller production runs or products that require more complex packaging. Platesetters allow greater flexibility in the types of materials used and the complexity of blister designs.

Both types of blister packaging machines are equipped with advanced technology to ensure precision and quality during the packaging process. They can be integrated with various functions such as automatic feeding systems, visual inspection systems and data logging functions to monitor production efficiency and product quality.

To sum up, blister packaging machines play a vital role in the manufacturing of blister packaging, which is widely recognized for its protective and user-friendly features. The benefits of blister packaging include extended shelf life, tamper resistance and increased convenience, making them ideal for a variety of industries. As technology continues to advance, blister packaging machines are becoming more sophisticated, allowing manufacturers to meet the growing demand for efficient, effective packaging solutions. Whether in the pharmaceutical industry or the consumer goods market, blister packaging machines are indispensable tools to ensure that products are safely packaged and presented aesthetically.

Post time: Oct-30-2024