In the ever-evolving world of healthcare, the need for efficient, safe and innovative solutions is paramount. One of the most significant advancements in the field of intravenous (IV) therapy has been the development of non-PVC soft-bag IV solutions. These solutions are not only safer for patients, but also better for the environment. The Soft-Bag Saline IV Solution Filling Machine Manufacturing Plant is at the forefront of this innovation, a state-of-the-art production line that is changing the way IV solutions are produced.

Non-PVC solution required

Traditionally, IV solutions have been packaged in polyvinyl chloride (PVC) bags. However, concerns about harmful chemicals in PVC leaching into the solution have led to a shift toward non-PVC alternatives. Non-PVC soft bags are made from materials that do not pose the same risks, making them a safer option for patients receiving IV therapy. Additionally, these bags are more flexible and lightweight, improving patient comfort and ease of use.

Soft bag brine filling machine

The Soft Bag Normal Saline IV Infusion Filling Machine Manufacturing Plant is a ground-breaking facility designed to meet the growing demand for non-PVC soft bag IV infusion solutions. This state-of-the-art production line uses the latest technology to ensure high efficiency and high quality in the manufacturing process.

Main features of the manufacturing plant

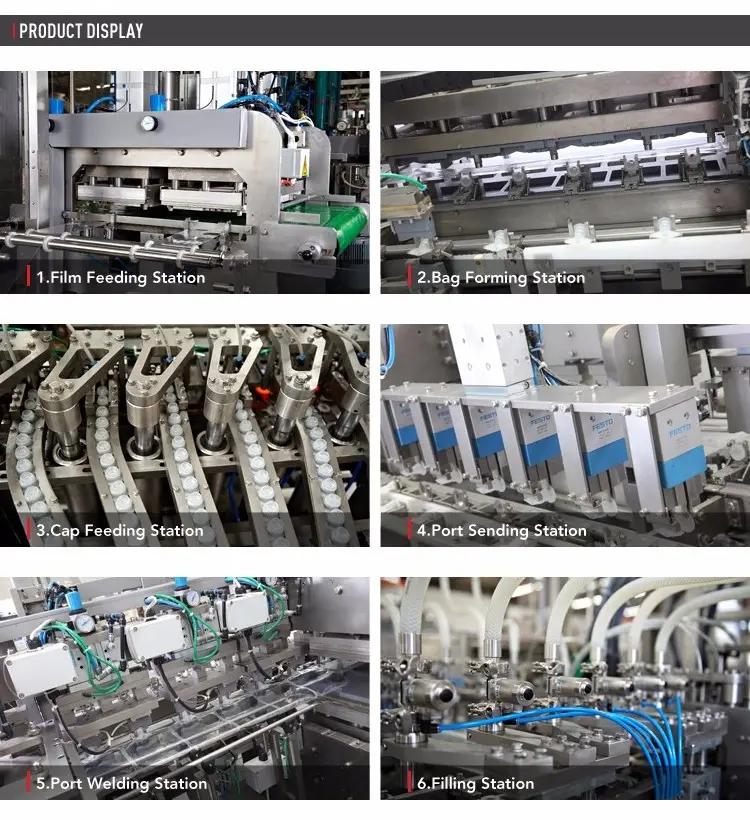

1. Automated production process: The manufacturing plant is equipped with a fully automated system that can handle multiple production stages. From film feeding and printing to bag making, filling and sealing, the entire process is streamlined into one machine. This automation not only reduces labor costs, but also minimizes the risk of human error, ensuring consistent quality of each batch of products.

2. Versatile filling capability: The LVP (Large Volume Parenteral) FFS (Form-Fill-Seal) line is designed to accommodate a wide range of solutions. It can automatically fill solutions from 50 ml to 5000 ml for a wide range of applications, including general purpose solutions, specialty solutions, dialysis solutions, parenteral nutrition, antibiotics, irrigation, and disinfection solutions. This versatility enables healthcare providers to effectively meet the needs of a wide range of patients.

3. Customizable Bag Design: IVEN, the company behind this innovative manufacturing facility, offers a variety of PP (polypropylene) bag designs. Customers can choose from single vessel ports, single or dual hard ports, and dual hose ports to get a customized solution that meets specific clinical requirements. This customization enhances the usability of IV solutions, making them more effective for healthcare providers.

4. Quality Assurance: The manufacturing plant adheres to strict quality control measures to ensure that each product meets the highest standards. Regular testing and monitoring throughout the production process ensures that IV infusions are safe and effective for patients.

Advantages of non-PVC soft bag infusion

Transitioning to non-PVC soft bag IV solutions offers many benefits to patients and healthcare providers:

Safe: Non-PVC material eliminates the risk of harmful chemical leaching, providing a safer option for patients receiving IV therapy.

Environmental Impact: Using non-PVC materials helps reduce environmental pollution as these bags are generally more recyclable than PVC bags.

Patient Comfort: The flexibility and lightness of the soft bag improves patient comfort, making the IV procedure more pleasant.

Efficiency: Automated production processes ensure healthcare providers have fast and reliable access to IV solutions, improving patient care.

The turnkey non-PVC soft bag IV fluid facility represents a significant leap forward in the production of IV therapies. With its advanced technology, automated processes, and customizable options, the manufacturing facility is expected to meet the growing demand for safe and effective IV fluids. As healthcare continues to evolve, innovations such as this will play a key role in enhancing patient care and safety.

At IVEN, we are committed to providing cutting-edge solutions that meet the needs of the healthcare industry. Our soft bag saline IV solution filling machine manufacturing plant is just one example of how we are leading the way in IV solution production. By prioritizing safety, efficiency, and customization, we are helping to shape the future of IV therapy.

Post time: Dec-06-2024