Manufacturing Companies for Syringe Gasket Manufacturers - Syringe Assembling Machine – IVEN

Manufacturing Companies for Syringe Gasket Manufacturers - Syringe Assembling Machine – IVEN Detail:

Brief Introduction:

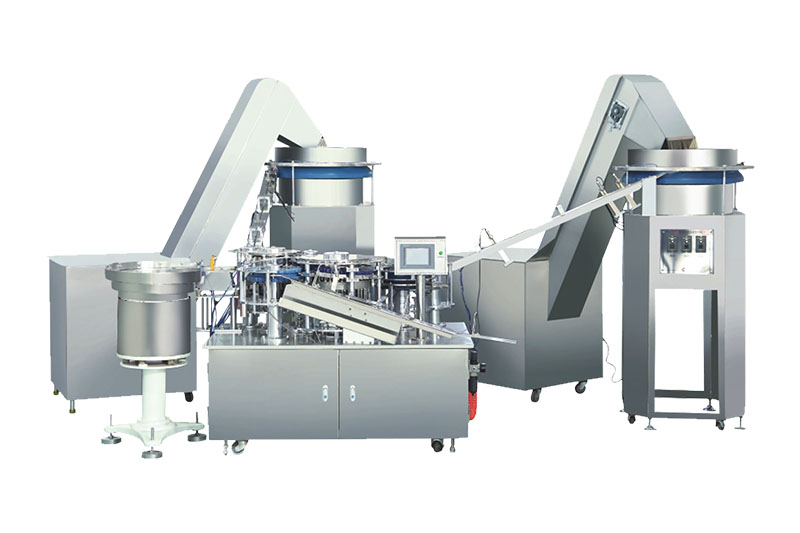

Our Syringe Assembling Machine is used for assembling syringe automatically. It can produce all kinds of syringes, including luer slip type, luer lock type, etc.

Our Syringe Assembling Machine adopts LCD display to display the feeding speed, and can adjust the assembly speed separately, with electronic counting. High efficiency, low power consumption, easy maintenance, stable operation, low noise, suitable for the GMP workshop.

Product Video

Product Description:

Our syringe assembling machine consists of feeding system and assembly mechanism.

Feeding system: feed 4 components of syringe (plunger/stopper/needle/barrel) to the assembly mechanism.

Feeding system are composed of feed bin and centrifugal feeder for barrel/plunger, hopper and feeder for needle/stopper.

Feeding system with photoelectric sensors, when assembling mechanism is full of products it will stop feeding, and when there is lack of products it will start working automatically.

Assembly Mechanism: assemble all parts of components together as a finished product. Usually, It completes 3 actions: action 1 – assemble plunger with rubber stopper; action 2 – assemble barrel with needle; action 3 – assemble plunger with stopper and barrel with needle.

Main Technical Parameters:

|

Model |

ZZ-001IV |

| Applicable Specification | 2ml~50ml |

| Production Capacity | 150-250pcs/min |

| Overall Dimension | 4200*3000*2100mm |

| Weight | 1500kgs |

| Power Supply | AC220V/3KW |

| Compressed Air Flow | 0.3m³/min |

Main Configuration List

|

No. |

Name |

Brand |

Remark |

|

1 |

Frequency converter | Mitsubishi (Japan) | |

|

2 |

Motor | Taizhou, China | |

|

3 |

Reducer | Hangzhou, China | |

|

4 |

Adjustable-speed motor | Mitsubishi (Japan) | |

|

5 |

Control system | Single chip microcomputer | |

|

6 |

Touch Screen | China | |

|

7 |

CCD vision sensor system | KEYENCE (Japan) | |

|

8 |

The housing material | SS 304, Plated metal | |

|

9 |

Dust cover | Aluminum profile |

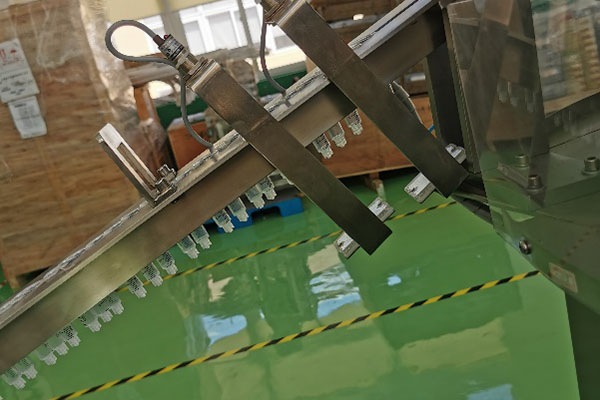

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by providing worth added design and style, world-class producing, and repair capabilities for Manufacturing Companies for Syringe Gasket Manufacturers - Syringe Assembling Machine – IVEN , The product will supply to all over the world, such as: Georgia, Paraguay, Mecca, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.