Hot-selling Gmp Clean Room - IV Infusion Glass Bottle Turnkey Project – IVEN

Hot-selling Gmp Clean Room - IV Infusion Glass Bottle Turnkey Project – IVEN Detail:

Product Description:

IVEN Pharmatech is the pioneer supplier of turnkey plants that provides integrated engineering solution for worldwide pharmaceutical factory such as IV solution, vaccine, oncology etc., in compliance with EU GMP, US FDA cGMP, PICS, and WHO GMP.

We provide the most reasonable project design, the high quality equipment and the customized service to different pharmaceutical and medical factories from A to Z for Non-PVC soft bag IV solution, PP bottle IV solution, Glass vial IV solution, Injectable Vial & Ampoule, Syrup, Tablets & Capsules, Vacuum blood collection tube etc.

Core description

SHANGHAI IVEN PHAMATECH is considered as leader for IV solution turnkey projects supplier.

In our turnkey offers we usually exclude those items that can be procured locally at reasonable prices by the customer itself (like land, buildings, brick wall parts…).

IVEN besides can provide the Turnkey project also can help client for below work:

– Advanced Know How Transfer for additional Glass bottle IV solutions.

– Post-Start up assistance

– Raw Materials and Consumables

– Black Utilities

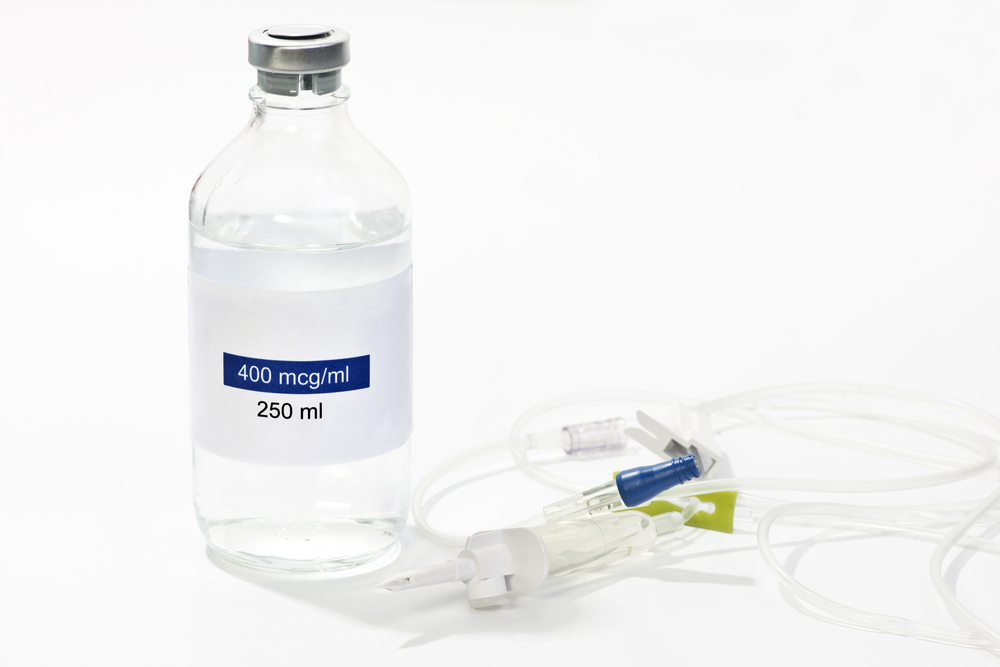

STANDARD IV SOLUTION PRODUCTS &TPN

- NaCl 0,18 – 2.7%

- Glucose 2,5 – 50%

- Sodium Lactate (Hartmanns’s) Solution

- Ringer Lactate

- Water For injection

- Sterile Water for Irrigation

- Sodium Chloride 0.9% for irrigation

- Sodium Chloride

- Potassium Chloride 0.15 – 0.3% in Sodium Chloride 0.9%

- Potassium Chloride 0.15 – 0.3% in Glucose 5%

TPN (Total Parenteral Nutrition)

- Amino acids

- Fat Emulsion

SPECIAL SOLUTIONS

- Paracetamol

- Plasma Expanders

- Mannitol

- Lidocainje hydrochloride 0.4% and glucose 5%

- Sodium bicarbonate 1.26 – 4.2%

- Phosphate IV solution

- Metronidazole

- Ciprofloxacin

- Levofloxacin

- Fluconazol

FROM DESIGN TO VALIDATION, WE ARE ALWAYS CONSIDERATION FOR OUR CLIENT.

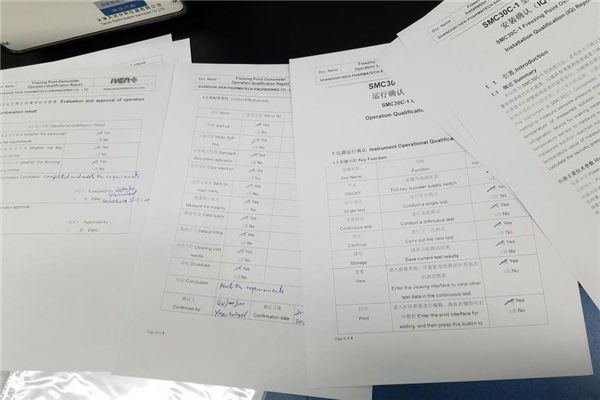

The standards of good manufacturing practice (cGMP) require special attention to risk assessment and verification procedures: “… it is requirement of good manufacturing identify the activities of validation necessary to demonstrate control critical aspects of particular operations. The significant changes made to installations, equipment and processes, which may affect product quality, should be validated. A procedure for risk assessment should be used to determine the scope and extent of validation.” The Validation Master Plan serves to make sure that all equipment, procedures, that may affect the quality or integrity or effectiveness of the product, are validated; it contains the general principles which comply during the validation task, and plans activities to be carried out for this purpose.

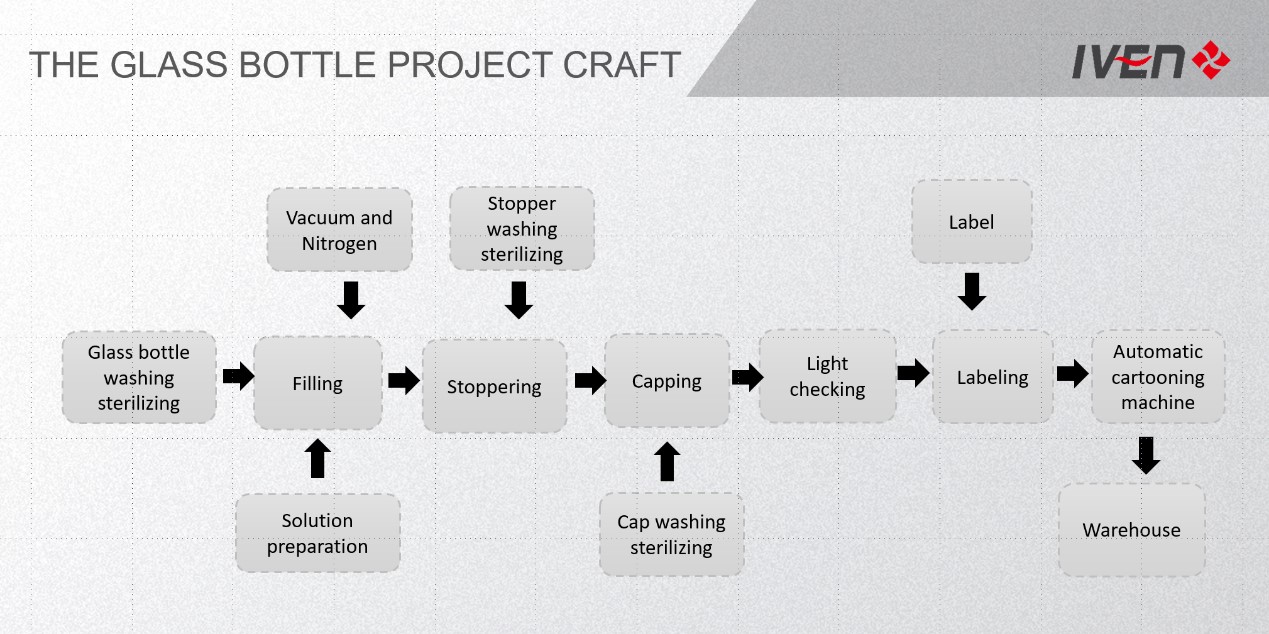

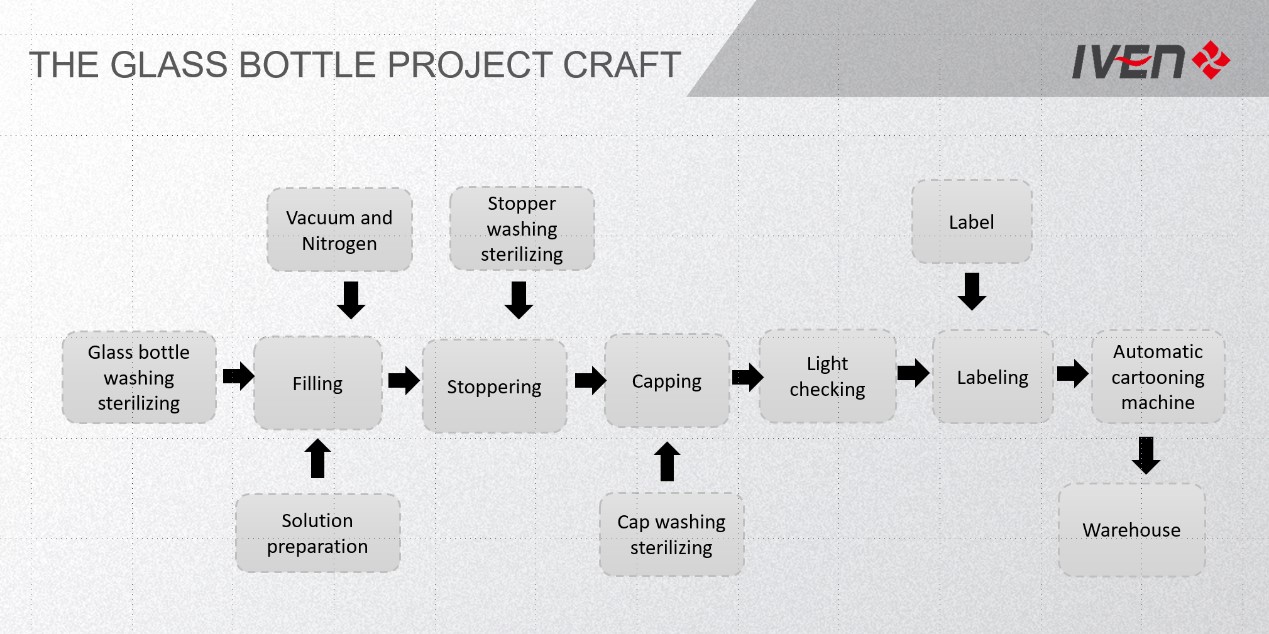

IVEN TURNKEY FOR IV FLUIDS AND PARENTERAL SOLUTIONS / STANDARD STEPS

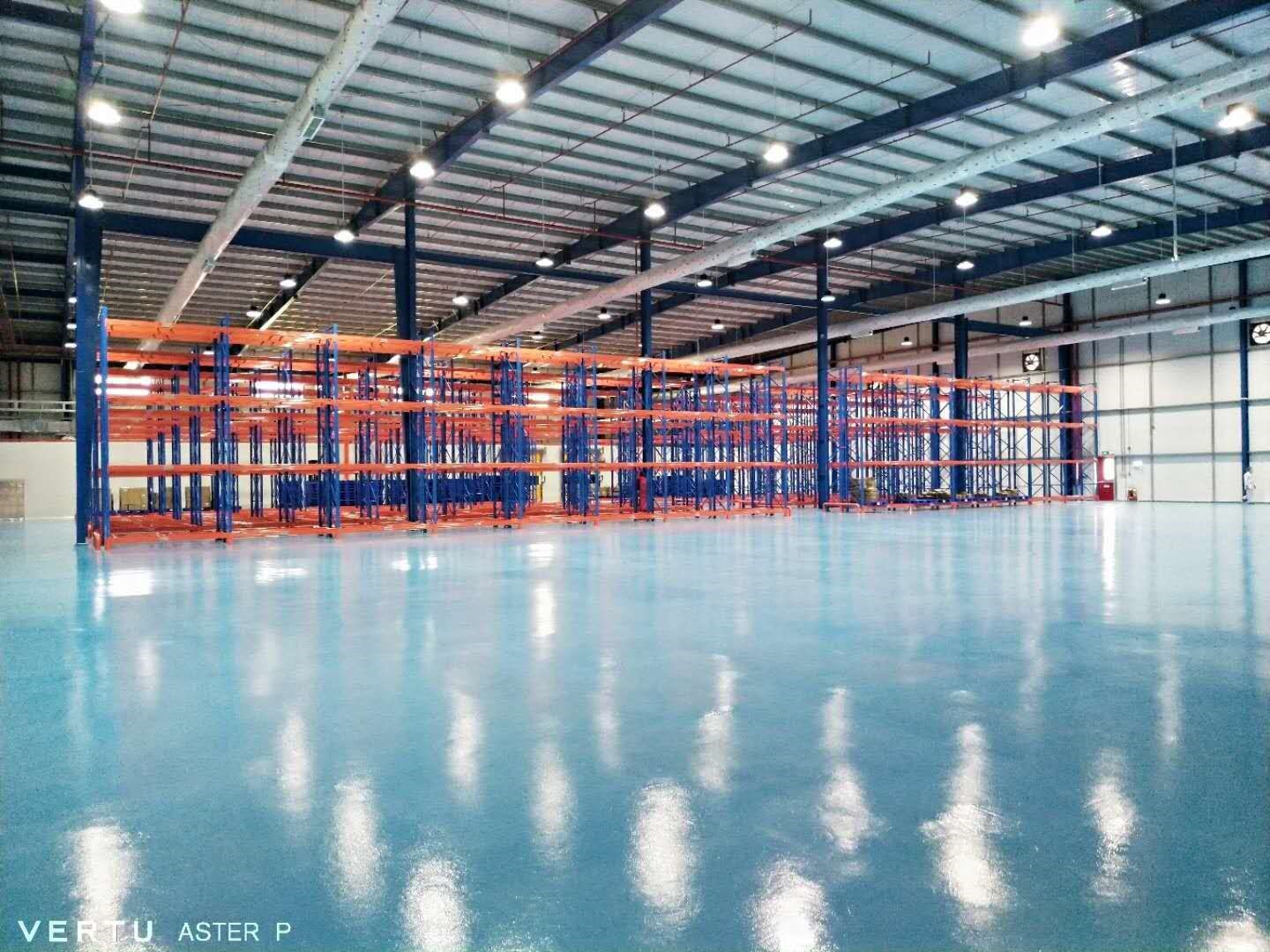

√ Basic Engineering √ Detailed Engineering √ Design Qualification √ Inlet Water Pretreatment Plant √ Pharmaceutical Water Systems (Softened, Purified and Distilled Water) √ Pharmaceutical Processing and Solution Preparation Systems √ Pharmaceutical Bottle washing, Filling, Inspecting, Packaging lines √ Clean Rooms √ Epoxy coating of the floors/PVC floor √ HVAC and air treatment plant √ Autoclave √ Pure Steam Generator and PS circuit √ Laboratories of Analysis (Microbiological / Chemical) √ Site Master Plan √ Validation Master Plan √ Installation √ Training √ Start up √ Technical Files & Documentation √ IQ/OQ √ PQ Protocols √ Validation at Site √ Standard Operating Procedures √ Initial Know How Transfer √ GMP preAudit √ Spareparts for n years

IVEN Oversea Turnkey Projects

Till now, we’ve already provided hundreds sets of pharmaceutical equipment and medical equipment to more than 40 countries. Meanwhile, we helped our customers to built the pharmaceutical and medical plant with turnkey projects in Russia, Uzbekistan, Tajikistan, Indonesia, Thailand, Saudi, Iraq, Nigeria, Uganda etc. All these projects won our customers and their government high comments.

IVEN profession and experience can help you finish whole IV solution turnkey plant in the shortest time and avoid all kinds of potential risks:

IVEN oversea pharmaceutical turnkey plants customers:

Meanwhile, we helped our customers to built 20+ pharmaceutical and medical turnkey plants in Russia, Uzbekistan, Tajikistan, Indonesia, Thailand, Saudi, Iraq, Nigeria, Uganda, Tanzania, Ethiopia, Myanmar etc, mainly for IV solution, injectable vials and ampoules. All these projects won our customers and their government high comments.

We also exported our IV solution production line to Germany.

Indonesia IV bottle turnkey plant

Vietnam IV bottle turnkey plant

Uzbekistan IV bottle turnkey plant

Thailand Injectable vial turnkey plant

Tajikistan IV bottle turnkey plant

Saudi Arabia IV bag turnkey plant

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our administration ideal for Hot-selling Gmp Clean Room - IV Infusion Glass Bottle Turnkey Project – IVEN , The product will supply to all over the world, such as: Namibia, Pakistan, Karachi, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!