Hot Selling for Sterilization Of Pharmaceutical - Syrup Washing Filling Capping Machine – IVEN

Hot Selling for Sterilization Of Pharmaceutical - Syrup Washing Filling Capping Machine – IVEN Detail:

Introduction:

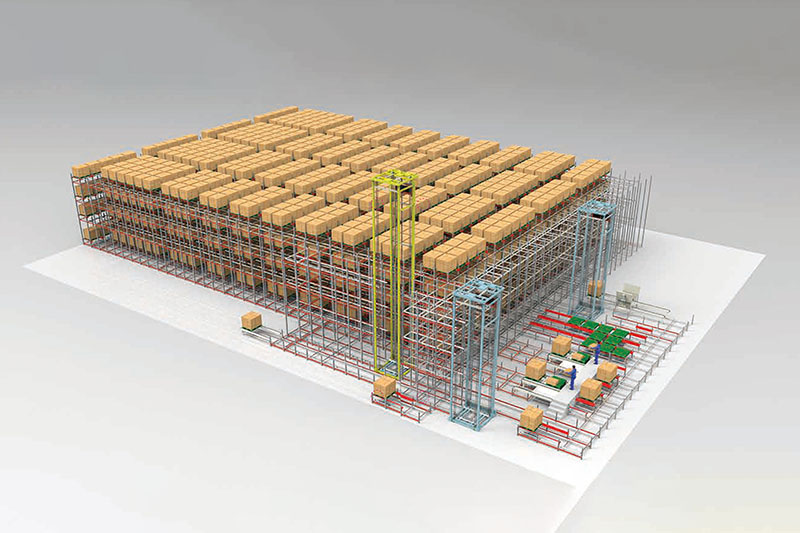

Syrup Washing Filling Capping Machine includes syrup bottle air /ultrasonic washing, dry syrup filling or liquid syrup filling and capping machine. It is integrate design, one machine can wash, fill and screw bottle in one machine, reduce investment and production cost. The whole machine is with very compact structure, small occupying area, and less operator. We can equip with bottle handing and labeling machine also for the complete line.

Application

For dry syrup or liquid syrup production, 50-500ml bottle.

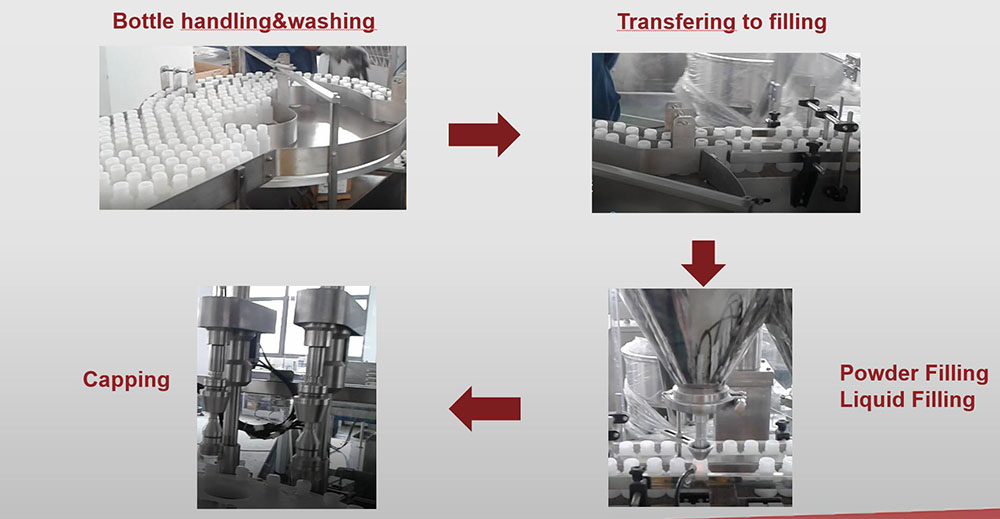

Production Procedures

Syrup Bottle Handling and Washing

According to plastic bottle or glass bottle, we equip with Ionic air washing or Ultrasonic washing station, to make sure most suitable technology for syrup bottle washing.

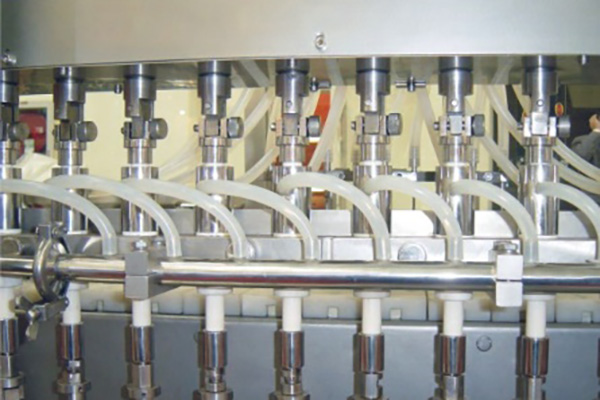

Syrup filling

After bottle washing, bottle go to filling station. Dry powder adopt screw filling, and liquid use peristaltic pump, high filling precision, and frequency control, production speed arbitrary regulation, automatic counting. It has auto-stop function, no bottle no filling.

Screw capping

With cap handling

Optional drying, stoppering station

High qualified capping rate

IVEN Syrup Washing Filling Capping Machine Advantages

1.Customized capacity from 3000-12000bottles/hour.

2.High automation, reasonable operation process and optimization of integration.

3.Suitable for different size syrup, dry and liquid types.

4.Intelligent & Humanized Operation System. Humanized design for each station , PLC +HMI control.

5.No bottle no filling, no bottle no capping.

6.High filling precision and qualified rate.

Machine Configuration

Tech Parameters

| Applicable Specs. S | 50-500ml |

| Working Speed | 3000-12000pcs/hour |

| Filling Method and Accuracy | Dry powder: screw filling, ±2%

Liquid solution: peristaltic pump filling, ±2% |

| Capping Method | Threaded Capping |

| Power | 380V/50HZ, 19KW |

| Speed controlling | Frequency control |

| Space Occupation | According to different capacity |

| *** Note: As products are constantly updated, please contact us for latest specifications. *** | |

Product detail pictures:

Related Product Guide:

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for Hot Selling for Sterilization Of Pharmaceutical - Syrup Washing Filling Capping Machine – IVEN , The product will supply to all over the world, such as: Zurich, Montpellier, Sydney, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.