Hot Selling for Ampoule Washing Machine Standard Operating Procedure - 30ml Glass Bottle Syrup Filling and Capping Machine for Pharmaceutical – IVEN

Hot Selling for Ampoule Washing Machine Standard Operating Procedure - 30ml Glass Bottle Syrup Filling and Capping Machine for Pharmaceutical – IVEN Detail:

Introduction

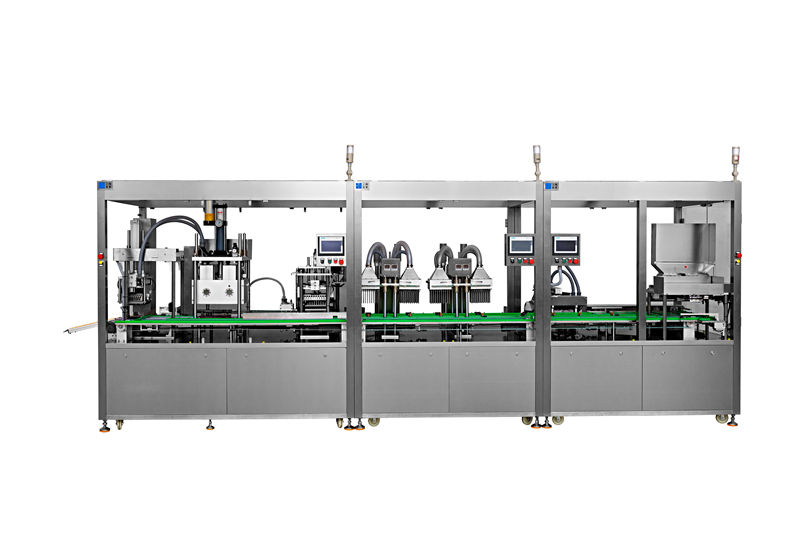

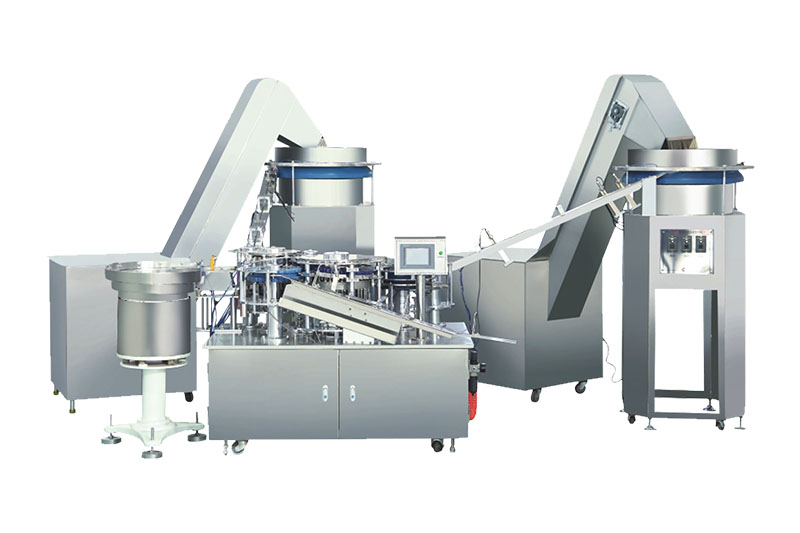

IVEN Syrup filling and capping machine

1.IVEN Syrup filling and capping machine is made up of CLQ ultrasonic washing ,RSM drying &sterilizing machine,DGZ filling & capping machine

2.IVEN Syrup filling and capping machine can complete following functions of ultrasonic washing ,flushing, (air charging, drying& sterilizing optional) ,filling and capping /screwing.

3.IVEN Syrup filling and capping machine is Suitable for Syrup and other other small dose solution , and with a labeling machine consisting an ideal production line.

IVEN Syrup filling and capping machine Process

Step 1

Bottle entering station

Ultrasonic bottle-washing machine are used to clear the inside and the outside of the medicinal vials and other cylinder bottles.

IVEN Syrup filling and capping machine new type chain conveyor is used to delivery bottles to dial wheel filling station, with features of low noise, no reverse pollution of clean air. Greatly reduce bottles collapsing ,lacking and breaking.

Step 2

Dial Wheel Station

The Chain conveyor of IVEN Syrup filling and capping machine is used to delivery bottles to dial wheel filling station, with features of low noise, no reverse pollution of clean air. Greatly reduce bottles collapsing ,lacking and breaking.

Step 3

Filling station

Reciprocated tracking filling system of IVEN Syrup filling and capping machine, with rotary dial wheel, high positioning accuracy, each filling head can be adjusted separatedly ,can achieve the function of no bottle no filling and anti-foaming filling.

Step 4

Capping station

IVEN Syrup filling and capping machine Optimized CAD design rolling knives angle and rolling head set, with good adaptability to irregular bottles, with easy operation and fast cap collating.

IVEN Syrup filling and capping machine Advantages

Imported variable control program, easy to operate

Filling accuracy, defoaming and not drip

No bottle no filling, no cap no capping

Easy capping design, low bottle breakage rate

Frequency stepless speed regulation

Filling with no pollution, long use life

IVEN Syrup filling and capping machine Application

Samples show:

Syrup filling and capping machine

Syrup Syrup Filling Line 30 Ml Glass Bottle

Syrup Syrup Filling Line 100 Ml Glass Bottle

Syrup Syrup Filling Line for Pharmaceutical

IVEN Syrup filling and capping machine Tech Specs

| Name | Specification |

| Over size | 2000*1100*2400mm |

| Total weight | 1300kg |

| Total power | 2.5kw |

| Filling heads | 16 |

| Filling accuracy | ≤±1% |

| Capping head | 12 |

| Capping qualification | ≥99.8% |

| Percent of damage | ≤0.1% |

Material & Application

Product detail pictures:

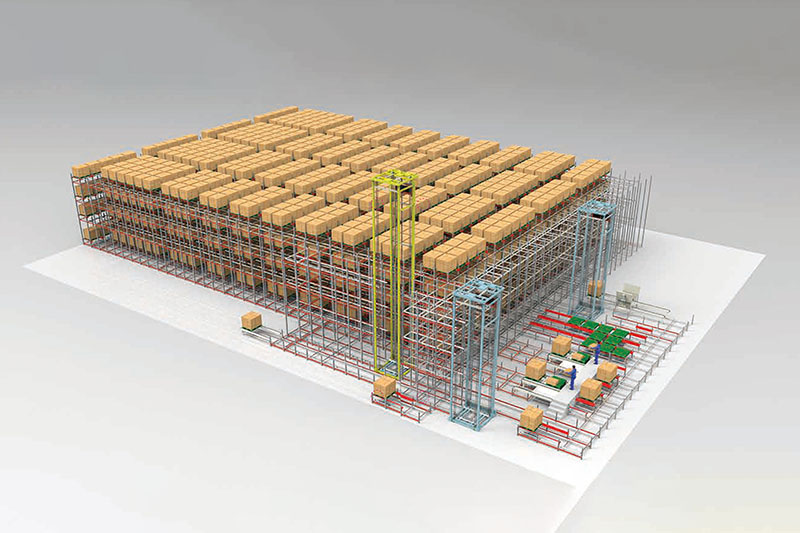

Related Product Guide:

Sticking for the perception of Creating goods of high quality and making good friends with people today from all around the world, we constantly set the interest of shoppers to begin with for Hot Selling for Ampoule Washing Machine Standard Operating Procedure - 30ml Glass Bottle Syrup Filling and Capping Machine for Pharmaceutical – IVEN , The product will supply to all over the world, such as: Italy, Malta, Canada, We have been fully aware of our customer's needs. We deliver high quality products, competitive prices and the first class service. We would like to establish good business relationships as well as friendship with you in the near future.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!