High Performance Syringe Mould Manufacturers - Syringe Assembling Machine – IVEN

High Performance Syringe Mould Manufacturers - Syringe Assembling Machine – IVEN Detail:

Brief Introduction:

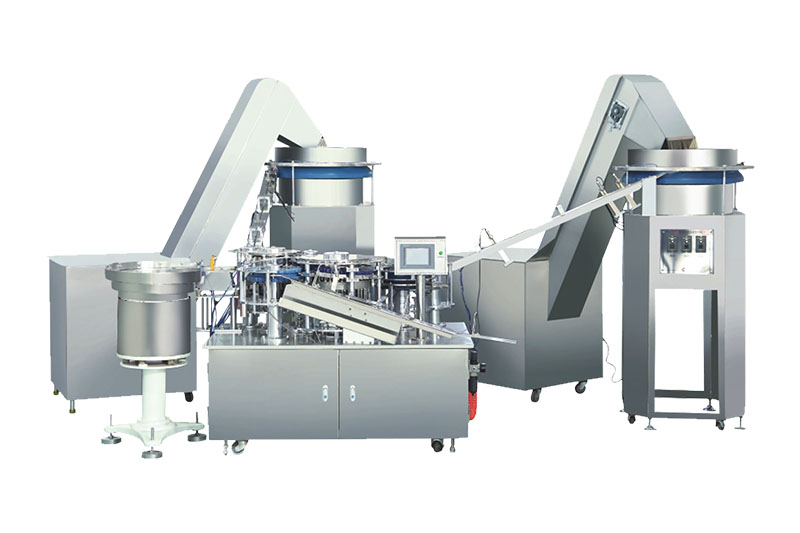

Our Syringe Assembling Machine is used for assembling syringe automatically. It can produce all kinds of syringes, including luer slip type, luer lock type, etc.

Our Syringe Assembling Machine adopts LCD display to display the feeding speed, and can adjust the assembly speed separately, with electronic counting. High efficiency, low power consumption, easy maintenance, stable operation, low noise, suitable for the GMP workshop.

Product Video

Product Description:

Our syringe assembling machine consists of feeding system and assembly mechanism.

Feeding system: feed 4 components of syringe (plunger/stopper/needle/barrel) to the assembly mechanism.

Feeding system are composed of feed bin and centrifugal feeder for barrel/plunger, hopper and feeder for needle/stopper.

Feeding system with photoelectric sensors, when assembling mechanism is full of products it will stop feeding, and when there is lack of products it will start working automatically.

Assembly Mechanism: assemble all parts of components together as a finished product. Usually, It completes 3 actions: action 1 – assemble plunger with rubber stopper; action 2 – assemble barrel with needle; action 3 – assemble plunger with stopper and barrel with needle.

Main Technical Parameters:

|

Model |

ZZ-001IV |

| Applicable Specification | 2ml~50ml |

| Production Capacity | 150-250pcs/min |

| Overall Dimension | 4200*3000*2100mm |

| Weight | 1500kgs |

| Power Supply | AC220V/3KW |

| Compressed Air Flow | 0.3m³/min |

Main Configuration List

|

No. |

Name |

Brand |

Remark |

|

1 |

Frequency converter | Mitsubishi (Japan) | |

|

2 |

Motor | Taizhou, China | |

|

3 |

Reducer | Hangzhou, China | |

|

4 |

Adjustable-speed motor | Mitsubishi (Japan) | |

|

5 |

Control system | Single chip microcomputer | |

|

6 |

Touch Screen | China | |

|

7 |

CCD vision sensor system | KEYENCE (Japan) | |

|

8 |

The housing material | SS 304, Plated metal | |

|

9 |

Dust cover | Aluminum profile |

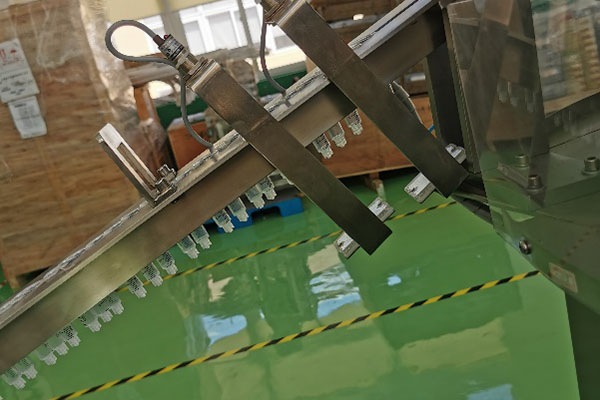

Product detail pictures:

Related Product Guide:

We now have a specialist, efficiency workforce to deliver excellent service for our purchaser. We always follow the tenet of customer-oriented, details-focused for High Performance Syringe Mould Manufacturers - Syringe Assembling Machine – IVEN , The product will supply to all over the world, such as: Barcelona, Oslo, Uruguay, We've more than 10 years exported experience and our products and solutions have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!