High Performance Syringe Mould Manufacturers - Hemodialysis Solution Production Line – IVEN

High Performance Syringe Mould Manufacturers - Hemodialysis Solution Production Line – IVEN Detail:

Hemodialysis Solution Production Line Introduction:

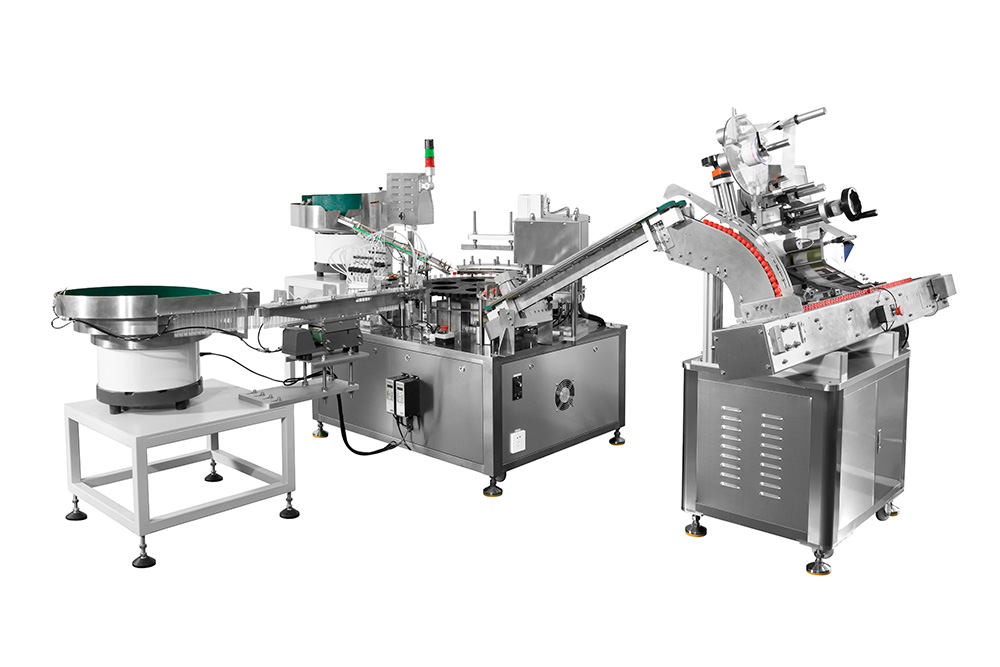

The Hemodialysis filling line adopts advanced German technology and is specially designed for dialysate filling. The part of this machine can be filled with a peristaltic pump or a 316L stainless steel syringe pump. It is controlled by PLC, with high filling accuracy and convenient adjustment of the filling range. This machine has reasonable design, stable and reliable operation, easy operation and maintenance, and fully meets GMP requirements.

Application

For Hemodialysis barrel washing filling capping.

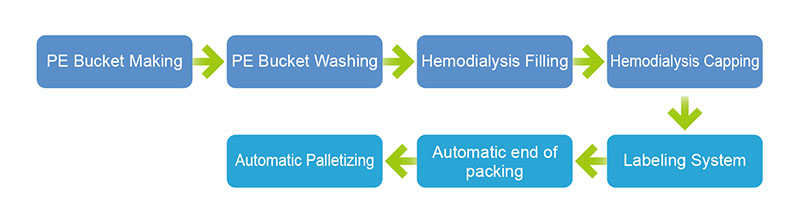

Hemodialysis Solution Production Line Procedures

Hemodialysis filling line

- High precision: adopt weigh filling system (METTLER TOLEDO weighing sensor), increase the filling precision. Special small ball conveying, make the bottle running stably on conveyor.

- Fast-slow filling valve, guarantee fast filling in earlier stage to save filling time, and slow filling in last stage to increase the filling precision. Motor top-bottom filling, reduce the foaming while filling.

- Mounted collect tray under filling nozzle in case of drip from the nozzle. Our nozzle has the function shut on/off to seal the nozzle mouth, guarantee no dripping touch to the bottle outside.

- Whole machine is controlled intelligently, bottle sensor reading, no bottle no filling, crash proof design for each container.

- Electric components adopt French Schneider, like PLC, HMI, inverter and breaker. integrate pneumatic controlling, more stable, safety, green and low consumption.

- Machine is fully covered by SS304, tempered glass door, better adaptability of various kinds of environment, anti-corrosive, and easy clean.

- Pipeline support CIP/SIP

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for High Performance Syringe Mould Manufacturers - Hemodialysis Solution Production Line – IVEN , The product will supply to all over the world, such as: New Delhi, Grenada, Kuala Lumpur, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Send your message to us:

Write your message here and send it to us