Good Quality Vial Filling Equipment - LVP Automatic Light Inspection Machine (PP bottle) – IVEN

Good Quality Vial Filling Equipment - LVP Automatic Light Inspection Machine (PP bottle) – IVEN Detail:

LVP automatic light inspection machine Introduction:

Automatic visual inspection machine can be applied to various pharmaceutical products, including powder injections, freeze-drying powder injections, small-volume vial/ampoule injections, large-volume glass bottle/plastic bottle IV infusion etc.

The inspection station can be configured according to customer actual needs, and targeted inspection can be configured for various foreign bodies in the solution, filling level, appearance and sealing etc.

During the inner liquid inspection, the inspected product is braked to a standstill during high-speed rotation, and the industrial camera continuously takes pictures to obtain multiple images, which are processed by the visual inspection algorithm independently developed to judge whether the inspected product is qualified.

Automatic rejection of unqualified products. The whole detection process can be traced, and the data is automatically stored.

High quality automatic inspection machine can help customers reduce labor costs, reduce lamp inspection error rate and guarantee the patients’ medication safety.

LVP automatic light inspection machine Feature:

1.Automatically complete the equidistant separation into bottles, and automatically eliminate the defective products according to the test results.

2.It can automatically rotate the bottle to be inspected at high speed, which is conducive to the movement of liquid impurities and facilitates the inspection.

3.The visual imaging principle is used to detect and it is more accurate to judge visible foreign matters.

4.PLC HMI operation, touch type LCD control panel.

5.It can detect the defects of rings, bottle bottom black spots and bottle caps.

6.Waterproof structure design is adopted partly, which is convenient for cleaning broken bottle. The broken bottle area can be directly washed with water.

LVP automatic light inspection machine Advantages:

1.Adopt full servo drive system to realize high-speed, stable and accurate operation and improve the quality of image acquisition.

2.Fully automatic servo control adjusts the height of the rotating plate to facilitate the replacement of various bottles of different specifications, and the replacement of specifications parts is convenient. 8

3.It can detect the defects of rings, bottle bottom black spots and bottle caps.

4.The software has a complete database function, manages the test formula, stores (it can print) test results, performs KNAPP test, and realizes the touch screen human-machine interaction.

5.The software has an offline analysis function, which can reproduce the detection and analysis process.

LVP automatic light inspection machine technical parameters:

|

Equipment model |

IVEN36J/H-150b |

IVEN48J/H-200b |

IVEN48J/H-300b |

||

|

Application |

50-1,000ml plastic bottle / soft PP bottle | ||||

|

Inspection items |

Fiber, hair, white blocks and other insoluble objects, bubbles, black spots and other appearance defects | ||||

|

Voltage |

AC 380V, 50Hz | ||||

|

Power |

18KW | ||||

|

Compressed air consumption |

0.6MPa, 0.15m³ /min | ||||

|

Max production capacity |

9,000pcs/h |

12,000pcs/h |

18,000pcs/h |

||

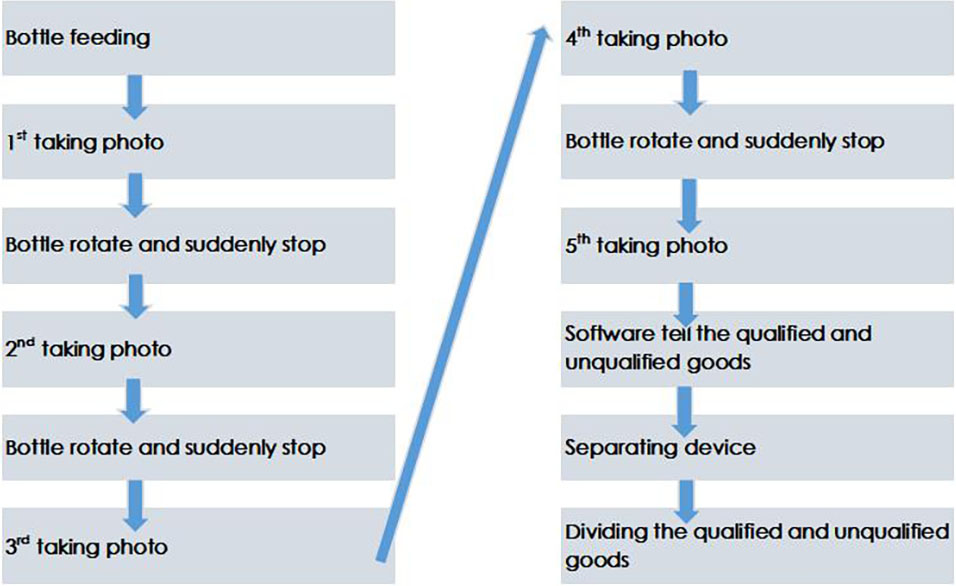

LVP automatic light inspection machine working process:

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Good Quality Vial Filling Equipment - LVP Automatic Light Inspection Machine (PP bottle) – IVEN , The product will supply to all over the world, such as: Netherlands, Australia, Italy, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.