Fast delivery Syringe Cutter Manufacturers - Micro Blood Collection Tube Production Line – IVEN

Fast delivery Syringe Cutter Manufacturers - Micro Blood Collection Tube Production Line – IVEN Detail:

Brief introduction

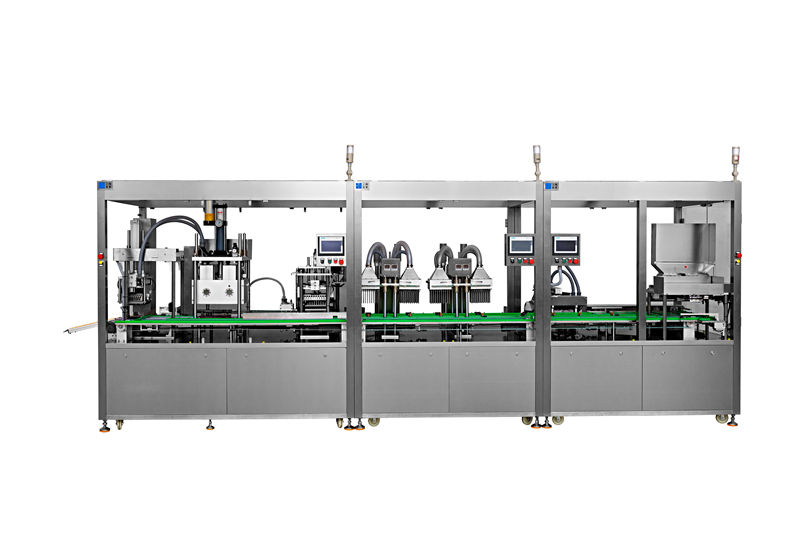

Micro blood collection tube serves as easy to collect blood form fingertip, earlobe or heel in neonates and pediatric patients. IVEN micro blood collection tube machine streamlines operations by allowing the automatic processing of the tube loading, dosing, capping and packing. It improves workflow with a one-piece micro blood collection tube production line and requires few personnel operate.

Our advantage

1. High degree of automation — fully automatic assembly operation, reasonable optimization and integration of operation process, automatic capping to finished product output. The whole production line only needs 1-2 skilled operators to meet the production requirements;

2. High cost performance, mobility and marriage rate of equipment — modular design, compact structure, and can be automatically assembled according to the actual production needs of customers.

3. High degree of human-machine dialogue — humanized station design, humanized human-machine interface program design, display multi-function alarm and auxiliary troubleshooting;

4. Process control, quality control – material shortage detection, dosing action detection, drying temperature detection, cap in place detection, missing cap detection and other detection, etc. Each process is tested and controlled, high qualified rate;

5. The dosing system is precise in dosing, and dosing the corresponding products in a targeted manner. The atomizing and dosing station is equipped with ultrasonic automatic cleaning nozzle function.

6. Ultrasonic automatic cleaning nozzle, and designed with a drying function, you can set the cleaning frequency according to process requirements, no need to clean the nozzle manually. (Atomizing and dosing station)

7. SUS304 material sheet metal, frame and door sheet adopt nano processing, steel structure frame, high rigidity and shock absorption welded steel structure frame.

Configuration Description

| Pneumatic | AIRTAC cylinder, solenoid valve, shangshun cylinder and other pneumatic components are used to ensure stable operation and long life. |

| Electrical appliances | Original Schneider (France) electrical appliances, Omron (Japan) and Leuze (Germany) testing originals, Mitsubishi (Japan) PLC, Siemens (Germany) man-machine interface, Panasonic (Japan) servo motor. |

| Dosing device | American FMI ceramic metering pump, domestic precision ceramic injection pump. (the plan has only one dosing station). |

| Main components | The material is made of stainless steel sheet metal, the frame and door are nano-processed, the steel structure frame, high-quality aluminum alloy, stable and reliable and easy to clean, in line with GMP requirements. |

Technical Parameters

|

Item |

Description |

| Applicable tube specification | Flat bottom micro tube. (based on the samples provided, four sets) |

| Production capacity | ≥ 5500 pieces / hour |

| Dosing method and precision | 2 nozzles FMI ceramic quantitative pump (air atomization) ≤ ± 6% (calculation base 10µL) |

| Drying method | 1 group, “PTC” heating, hot air drying |

| Power supply | 380V / 50HZ |

| Power | Assembly line ~ 6 KW |

| Clean compressed air pressure | 0.6-0.8Mpa |

| Air consumption | <300L / min, air inlet G1 / 2, air pipe Ø12 |

| Equipment dimension: length, width and height | 3000 (+ 1000) * 1200 (+ 1000) * 2000 (+ 300 alarm light) mm |

Product detail pictures:

Related Product Guide:

Our commission is to serve our buyers and purchasers with most effective good quality and aggressive portable digital goods for Fast delivery Syringe Cutter Manufacturers - Micro Blood Collection Tube Production Line – IVEN , The product will supply to all over the world, such as: Uruguay, Bahrain, Thailand, We follow up the career and aspiration of our elder generation, and we're eager to open up a new prospect in this field, We insist on Integrity, Profession, Win-win Cooperation, because we have now a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.