Cartridge Filling Production Line

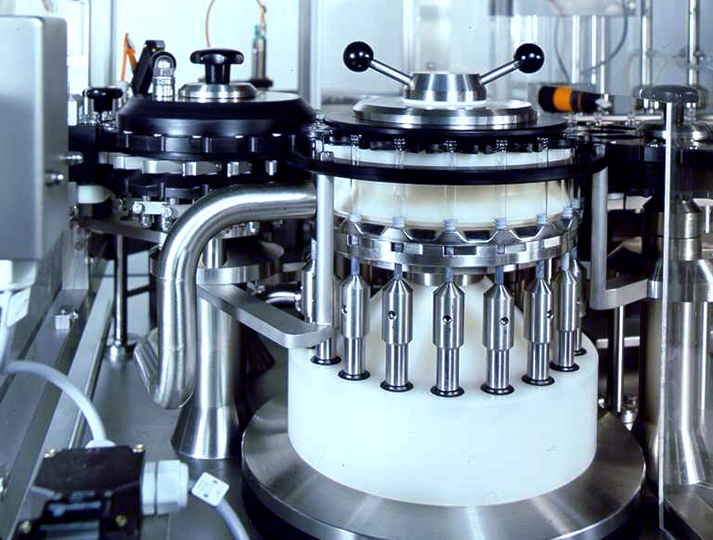

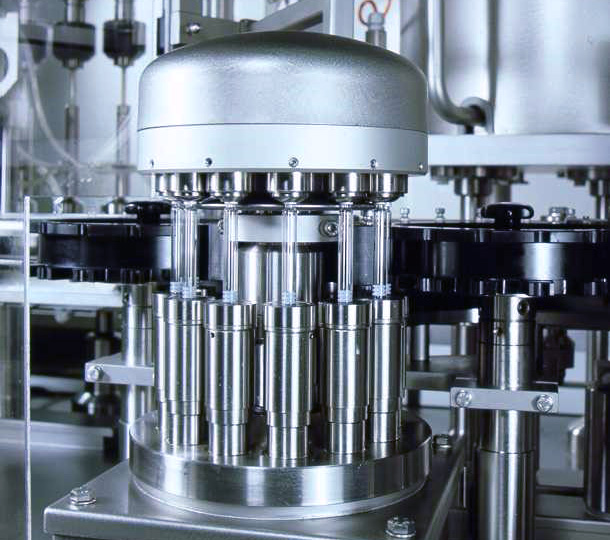

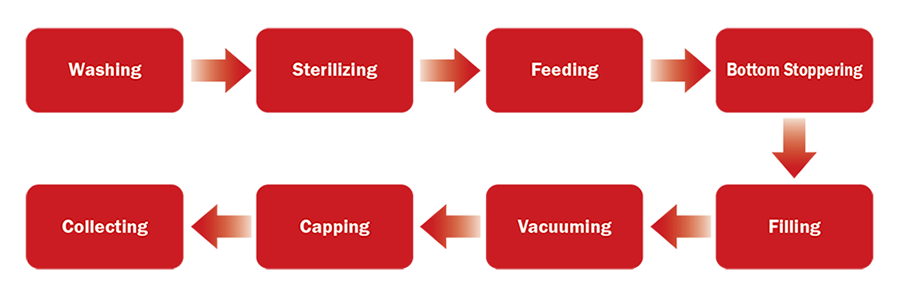

IVEN cartridge filling production line (carpule filling production line) welcomed a lot for our customers to produce cartridges/carpules with bottom stoppering, filling, liquid vacuuming (surplus liquid), cap adding, capping after drying and sterilizing. Full safety detection and intelligent control to guarantee stable production, like no cartridge/carpule, no stoppering, no filling, auto material feeding when it is running out.

Cartridges/Carpules feeding wheel after sterilization → Bottom part stoppered → Conveyed to filling station → Filled the 2nd time to full and vacuuming the redundant solution → Conveyed to the capping station → Conveyed to cartridges/carpules collection plate

|

No |

Item |

Brand & Material |

|

1. |

Servo motor |

Schneider |

|

2. |

Touch Screen |

Mitsubishi |

|

3. |

Ball screw |

ABBA |

|

4. |

Breaker |

Schneider |

|

5. |

Relay |

Panasonic |

|

6. |

Filling pump |

Ceramic pump |

|

7. |

Switching power supply |

Mingwei |

|

8. |

Solution contact part |

316L |

|

No |

Item |

Description |

|

1. |

Applicable range |

1-3 ml cartridge |

|

2. |

Production capacity |

80-100 cartridges/min |

|

3. |

Filling heads |

4 |

|

4. |

Vacuum consumption |

15m³/h, 0.25Mpa |

|

5. |

Stoppering heads |

4 |

|

6. |

Capping heads |

4 |

|

7. |

Power |

4.4kw 380V 50Hz/60Hz |

|

8. |

Filling accuracy |

≤ ± 1% |

|

9. |

Dimension( L*W*H) |

3430×1320×1700mm |