BFS (Blow-Fill-Seal) Solutions for Intravenous (IV) and Ampoule Products

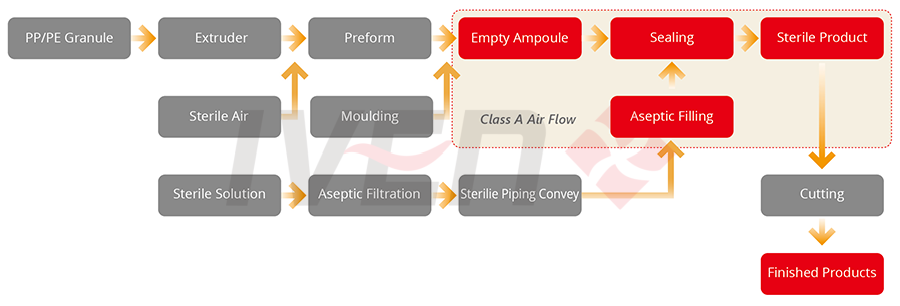

Blow-Fill-Seal production line adopts specialized aseptic packaging technology. It can work continuously and blow the PE or PP granules to container, then finish filling and sealing automatically and produce the container in a quick and continuous way. It combines several manufacturing processes in one machine, which can finish blowing-filling-sealing processes in one working station under the aseptic condition, to make sure the safety in use.

It can be widely used in the terminal sterilization products and aseptic products such as large volume IV bottles, small volume injectable ampoules or eye drops etc. This blow-fill-seal technology has the features of sterility, no particles, no pyrogen, and recommended by USA Pharmacopeia.

| NO | Description | Parameter |

| 1 | Deflash way | Outside deflash |

| 2 | Power Source | 3P/AC,380V/50HZ |

| 3 | Machine Structure | Black and white separated area |

| 4 | Packing Materials | PP/PE/PET |

| 5 | Specification | 0.2-5ml, 5-20ml, 10-30ml, 50-1000ml |

| 6 | Capacity | 2400-18000BPH |

| 7 | Filling Accuracy | ±1.5% for pure water.(5ml) |

| 8 | Manufacturing Standard | cGMP, Euro GMP |

| 9 | Electrical Standard | IEC 60204-1 electrical equipment for safety machineryGB/T 4728 Graphical symbols for diagrams |

| 10 | Compressed Air | Oil and water free,@ 8bar |

| 11 | Cooling Water | 12℃ pure water @ 4bar |

| 16 | Pure Steam | 125℃ @ 2bar |

| Model | Cavity | Capacity (Bottle per Hour) | Specification |

| BFS30 | 30 | 9000 | 0.2-5ml |

| BFS20 | 20 | 6000 | 5-20ml |

| BFS15 | 15 | 4500 | 10-30ml |

| BFS8 | 8 | 1600 | 50-500ml |

| BFS6 | 6 | 1200 | 50-1000ml |

| BFSD30 | Double 30 | 18000 | 0.2-5ml |

| BFSD20 | Double 20 | 12000 | 5-20ml |

| BFSD15 | Double 15 | 9000 | 10-30ml |

| BFSD8 | Double 8 | 3200 | 50-500ml |

| BFSD6 | Double 6 | 2400 | 50-1000ml |

Send your message to us:

Write your message here and send it to us