2020 New Style Leclerc Ampoule Machine A Coudre - Vial Liquid Filling Production Line – IVEN

2020 New Style Leclerc Ampoule Machine A Coudre - Vial Liquid Filling Production Line – IVEN Detail:

Introduction

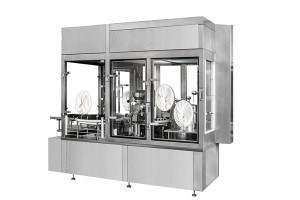

The Vial liquid filling production line includes vertical ultrasonic washing machine, RSM sterilizing drying machine, filling and stoppering machine, KFG/FG capping machine. This line can work together as well as independently. It can complete the following functions of ultrasonic washing, drying& sterilizing, filling& stoppering, and capping.

Product Video

Application:

For glass vial production.

Production Procedures:

Step 1

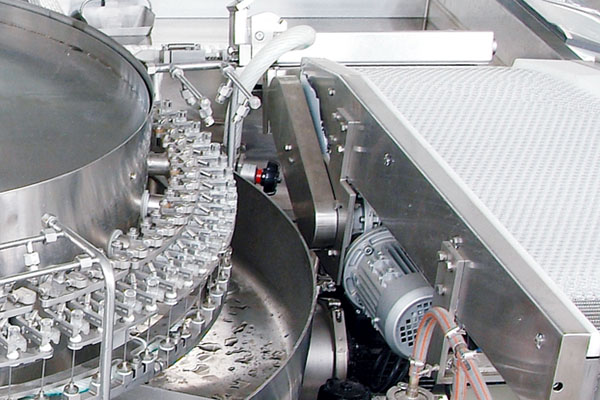

Ultrasonic washing

Ultrasonic bottle-washing machine are used to clear the inside and the outside of the medicinal vials and other cylinder bottles.

It has the following characteristics: Net belt conveyor vials infeed continuous; Start by spray and ultrasonic cleaning to strengthen the cleaning effect. Continuous rotation system. movement system, vials hold by the unique diamond clamp.

Recommending washing procedure: 7 washing station allocated as follows:

NO.1 & No.2 stations: Internal and external spraying with circulating water.

NO.3 station: Internal blowing with asepsis compressed air.

NO.4 station: using the WFI clean the internal of the vials. In this station, there has four nozzles washing the vial outside.

NO.5 station: Internal blowing with asepsis compressed air.

NO.6 station: Internal spraying with WFI .

NO.7 station: Blowing the asepsis compressed air to the internal of the vial twice. At the same time, there has four nozzles blowing the vial outside.

Step 2

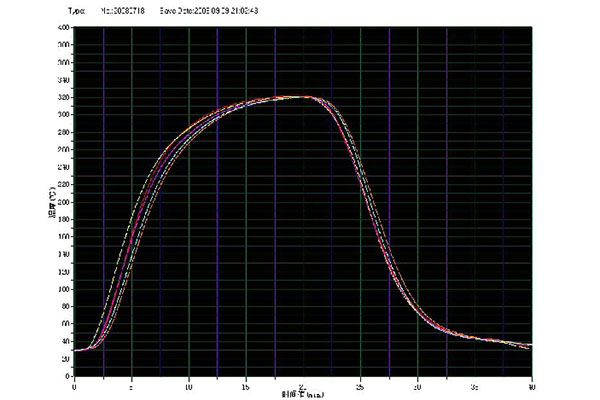

Sterilizing& Drying

Laminar flow sterilization tunnel used for washed vials dry sterilization and remove heat, It can reach the highest temperature 320℃, efficient sterilization time over 7minutes.(for 3Logs pyrogen redcution).

It has three working area (Preheat area, heating area, cooling area). The three working area installed on the steel base plate (the surface treated with chrome). Protective plate is used AISI304 which had been special treated.

Step 3

Filling& Stoppering

Aseptic Liquid Filling Machine is a new type vial filler developed by the study of the products both in domestic and abroad. It has various kinds of advanced technology on the bases of integration and prolongation, and is applicable in production line.

Step 4

Capping

Capping Machine is suitable for sealing procedure of vial by aluminum cap. It is continuous type of machine, by single capping disc with advantages of high-speed, low damaged and attractive appearance.

Vial Liquid Production Line Advantages

1.The compact line realizes single linkage, continuous operation from washing, sterilizing& drying,filling& stoppering, and capping. The whole production process realizes cleaning operation; protects products from contamination, meets the GMP production standard.

2.Full servo control.

3.Transparent self-lifting protective cover with humid air outlet, electric screw control, safe and easy to maintenance.

4.For customers’ liquid medicine and filling accuracy requirements, the ceramic pump filling system is selected, which can effectively ensure the filling accuracy and can be flexibly switched.

5.The stoppering form of inserting while rotating can effectively ensure the stoppering effect.

6.Capping machine: No Vial – No Capping, No Stopper – No Capping, Vacuum absorb aluminum scrap device.

Machine Configuration

Tech Parameters

| Model | Production line | Suitable size | Output(max) | Power | Net weight | Overall size |

| BXKZ I | CLQ 40 | 2.25ml | 6000-12000 pcs/h | 69.8KW | 7500Kg | 9930×2500×2340mm |

| RSM 620/44 | ||||||

| KGF 8 | ||||||

| BXKZII | CLQ 60 | 2.25ml | 8000-18000 pcs/h | 85.8KW | 8000Kg | 10830×2500×2340mm |

| RSM 620/60 | ||||||

| KGF10 | ||||||

| BXKZ III | CLQ 80 | 2.25ml | 10000-24000 pcs/h | 123.8KW | 8100Kg | 10830×2500×2340mm |

| RSM 900/100 | ||||||

| KGF 12 |

*** Note: As products are constantly updated, please contact us for latest specifications. ***

Excellent customer

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for 2020 New Style Leclerc Ampoule Machine A Coudre - Vial Liquid Filling Production Line – IVEN , The product will supply to all over the world, such as: Vancouver, Tajikistan, Houston, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.